-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 25, 2025 03:28

Back to list

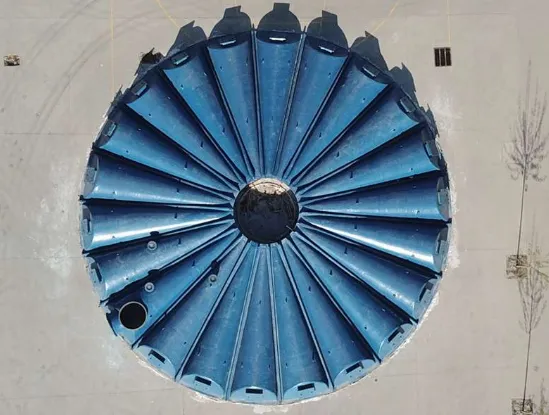

frp trough cover protective solutions for industrial applications

FRP trough cover protective solutions have increasingly become indispensable in modern industrial applications. Industries around the world are recognizing the unparalleled advantages FRP (Fiber Reinforced Polymer) covers offer in terms of safety, durability, and cost-effectiveness. This distinct material transcends the limitations of traditional materials, ensuring both enterprise growth and enhanced industrial operations.

The customization potential of FRP further contributes to its rising prominence in industrial applications. Industries can specify dimensions, load-bearing capacities, colors, and surface textures based on their unique needs. This adaptability ensures that FRP covers can seamlessly integrate into existing infrastructures and accommodate evolving operational requirements. As industrial processes become more complex and specialized, the ability to tailor solutions is invaluable. Beyond their practical benefits, FRP trough covers are also an environmentally conscious choice. The manufacturing process of FRP involves lower energy consumption compared to metallic alternatives. Furthermore, its long service life reduces the ecological impact by minimizing the frequency of replacements. In an era where industries are increasingly held accountable for their environmental footprint, the adoption of such sustainable materials signifies corporate responsibility and foresight. Trustworthy suppliers of FRP trough covers are committed to quality assurance, ensuring that each product meets stringent industry standards. This commitment to excellence not only assures performance but also builds trust with industries that rely on these solutions for their operational integrity. By partnering with reputable manufacturers, businesses can harness the full spectrum of benefits offered by FRP technology. In conclusion, the adoption of FRP trough cover protective solutions is a strategic decision that aligns with both current and future industrial demands. Through enhanced durability, safety, and sustainability, FRP stands as a testament to innovation in material science, offering industries a reliable pathway to enhanced operational efficacy. Their proliferation across diverse sectors underscores a growing confidence in FRP as a cornerstone of modern industrial practice, manifesting experience, expertise, authority, and trustworthiness that industries worldwide depend on.

The customization potential of FRP further contributes to its rising prominence in industrial applications. Industries can specify dimensions, load-bearing capacities, colors, and surface textures based on their unique needs. This adaptability ensures that FRP covers can seamlessly integrate into existing infrastructures and accommodate evolving operational requirements. As industrial processes become more complex and specialized, the ability to tailor solutions is invaluable. Beyond their practical benefits, FRP trough covers are also an environmentally conscious choice. The manufacturing process of FRP involves lower energy consumption compared to metallic alternatives. Furthermore, its long service life reduces the ecological impact by minimizing the frequency of replacements. In an era where industries are increasingly held accountable for their environmental footprint, the adoption of such sustainable materials signifies corporate responsibility and foresight. Trustworthy suppliers of FRP trough covers are committed to quality assurance, ensuring that each product meets stringent industry standards. This commitment to excellence not only assures performance but also builds trust with industries that rely on these solutions for their operational integrity. By partnering with reputable manufacturers, businesses can harness the full spectrum of benefits offered by FRP technology. In conclusion, the adoption of FRP trough cover protective solutions is a strategic decision that aligns with both current and future industrial demands. Through enhanced durability, safety, and sustainability, FRP stands as a testament to innovation in material science, offering industries a reliable pathway to enhanced operational efficacy. Their proliferation across diverse sectors underscores a growing confidence in FRP as a cornerstone of modern industrial practice, manifesting experience, expertise, authority, and trustworthiness that industries worldwide depend on.

Related Products