-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

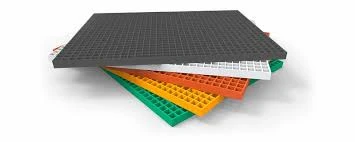

frp valve

Understanding FRP Valves A Comprehensive Overview

FRP (Fiber Reinforced Plastic) valves are increasingly becoming the go-to choice in various industrial applications due to their outstanding properties. These valves are engineered from a composite material that combines plastic with fiber reinforcements, typically glass or carbon fibers. This unique composition gives FRP valves remarkable strength while keeping them lightweight, making them ideal for a range of settings, particularly in environments where corrosion and high-stress conditions are a concern.

Understanding FRP Valves A Comprehensive Overview

Moreover, FRP valves are highly customizable. They can be manufactured in various shapes, sizes, and pressure ratings to meet specific operational requirements. This versatility means they can be used in diverse industries, including water treatment, chemical processing, food production, and even oil and gas. Their ability to withstand extreme temperatures and pressures adds to their appeal, as they can handle a wide range of operational scenarios.

frp valve

In addition to their physical properties, FRP valves are also noted for their ease of installation and lightweight nature. Compared to their metal counterparts, FRP valves are significantly easier to transport and install, which can lead to reduced labor costs and shorter project timelines. Furthermore, FRP materials are non-conductive, which can be an essential feature in applications where electrical isolation is necessary.

However, it is important to consider some limitations of FRP valves. They may not be suitable for high-temperature applications beyond certain thresholds, and their use in high-pressure scenarios is often contingent on the specific design and material of the valve. Additionally, the initial cost of FRP valves might be higher than traditional options, but this is typically offset by their long-term savings in maintenance and durability.

In conclusion, FRP valves represent a significant advancement in valve technology, offering myriad benefits such as corrosion resistance, lightweight design, and customizability. As industries continue to seek efficient and durable solutions, the demand for FRP valves is expected to rise, solidifying their place as a critical component in modern industrial applications. For companies looking to enhance their operations, investing in FRP valves could prove to be a pivotal step in achieving greater efficiency and reliability.