-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

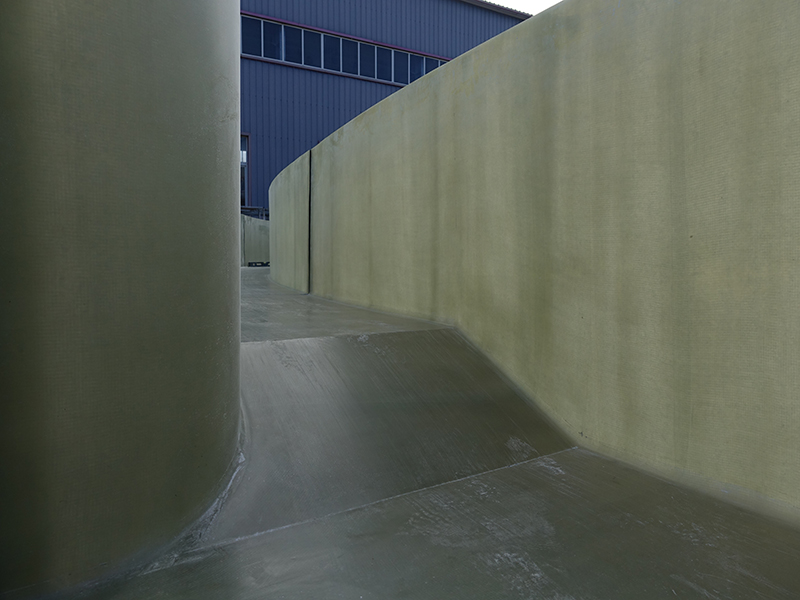

frp valve

Understanding FRP Valves An Overview of Their Applications and Benefits

FRP (Fiberglass Reinforced Plastic) valves are increasingly gaining popularity in various industrial applications due to their excellent corrosion resistance, lightweight nature, and impressive mechanical properties. These valves are primarily designed for handling corrosive fluids and gases, making them ideal for industries such as chemical processing, oil and gas, wastewater treatment, and many others. This article will explore the unique characteristics, advantages, and applications of FRP valves, highlighting their significance in modern industrial operations.

Characteristics of FRP Valves

FRP valves are made from a composite material that combines a plastic matrix, typically polyester or vinyl ester resin, reinforced with glass fibers. This unique construction offers several inherent characteristics

1. Corrosion Resistance One of the most significant advantages of FRP valves is their ability to withstand corrosion from aggressive chemicals. Unlike traditional metal valves, FRP does not rust or corrode, which prolongs the lifespan of the valves and reduces maintenance costs.

2. Lightweight FRP valves are much lighter than their metal counterparts, making them easier to handle, install, and maintain. This lightness also reduces the structural load on piping systems.

3. High Strength-to-Weight Ratio The addition of glass fibers significantly enhances the mechanical strength of FRP valves, allowing them to withstand high pressure and temperature conditions common in industrial processes.

4. Thermal Insulation FRP has low thermal conductivity, reducing heat transfer and minimizing thermal shock in applications involving extreme temperature fluctuations.

Advantages of Using FRP Valves

The use of FRP valves comes with numerous advantages that make them an attractive choice for industries dealing with corrosive substances

1. Cost-Effective While the initial cost of FRP valves may be higher than that of traditional valves, their durability and low maintenance needs lead to significant cost savings over time. The reduction in corrosion-related failures also means less downtime and fewer replacements.

frp valve

2. Safety FRP valves eliminate the risk of leaks associated with corrosive substances, enhancing safety for workers and the environment. Their non-conductive properties minimize the risk of electrical hazards.

3. Versatility FRP valves can be engineered to meet specific requirements for different industrial applications. They can be produced in various sizes, pressure ratings, and configurations, making them suitable for a wide range of operating conditions.

4. Environmentally Friendly The extended lifespan and reduced maintenance of FRP valves contribute to environmental sustainability. Their resistance to corrosion leads to fewer leaks and spills, which is crucial in protecting ecosystems from chemical contaminants.

Applications of FRP Valves

FRP valves find applications across various industries due to their superior properties. Some common applications include

1. Chemical Processing In the chemical manufacturing industry, FRP valves are employed to transport aggressive chemicals, acids, and alkalis without the risk of corrosion.

2. Water and Wastewater Treatment These valves are ideal for handling corrosive effluents and sewage, ensuring reliable operation in harsh conditions while reducing the risk of leaks.

3. Oil and Gas Within the oil and gas sector, FRP valves are used in offshore platforms and refineries, where their corrosion resistance is critical against salty seawater and other aggressive mediums.

4. Food Processing The non-toxic nature of FRP makes it suitable for food and beverage applications, notably in processes where hygiene and contamination prevention are essential.

Conclusion

In conclusion, FRP valves represent a versatile and durable solution for industries dealing with corrosive materials. Their unique characteristics, such as corrosion resistance, lightweight nature, and safety features, make them a preferred choice over traditional materials. By utilizing FRP valves, industries can achieve enhanced operational efficiency, lower maintenance costs, and contribute to a safer and more sustainable environment. As industrial processes continue to evolve and become more complex, the importance of reliable and effective valve solutions, such as FRP, will undeniably grow.