-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 17, 2025 05:10

Back to list

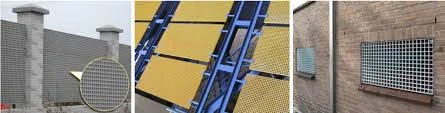

Fans & Dampers & Demisters

Fiber Reinforced Plastic (FRP) valves represent a breakthrough in fluid control systems, offering superior performance in harsh environments where traditional materials might falter. The modern industrial landscape seeks equipment that can withstand extreme conditions, maintain high durability, and deliver reliable performance. FRP valves meet these criteria, providing an ideal solution for sectors such as chemical processing, wastewater management, and seawater applications.

Experts in fluid dynamics and materials engineering consistently validate the performance and benefits of FRP valves. Academic and industrial research reveal the low maintenance requirements and operational longevity of FRP valves compared to traditional alternatives. This body of research confers an authoritative stance on the use of these valves, encouraging their adoption across various industries. The manufacturing of FRP valves also contributes to their environmental friendliness. As industries pivot towards sustainable practices, FRP valves emerge as a preferable choice due to their reduced carbon footprint during production and longer operational life that minimizes waste generation. Trust in FRP valves is bolstered by industry certifications and compliance with international standards. Manufacturers engage in rigorous testing processes to ensure that each product meets stringent performance metrics. Certifications from bodies such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide assurance to end-users about the quality and reliability of the valves. For professionals considering the integration of FRP valves into their systems, firsthand experiences and case studies are pivotal. Engineers report significant improvements in system performance and cost efficiency post-adoption of FRP valves. Feedback from plant supervisors and maintenance teams frequently highlights the decrease in unscheduled downtime and reduced frequency of part replacements, further reinforcing the trustworthiness and efficacy of these components. In conclusion, FRP valves are not merely an alternative to conventional options; they are a transformative force within industries sensitive to corrosion, weight, and durability challenges. Their extensive use in modern applications is prompted by their proven performance capabilities and substantial long-term economic benefits. As industries continually adapt to meet demanding operational standards and environmental considerations, FRP valves remain at the forefront as a reliable and authoritative option for fluid control needs.

Experts in fluid dynamics and materials engineering consistently validate the performance and benefits of FRP valves. Academic and industrial research reveal the low maintenance requirements and operational longevity of FRP valves compared to traditional alternatives. This body of research confers an authoritative stance on the use of these valves, encouraging their adoption across various industries. The manufacturing of FRP valves also contributes to their environmental friendliness. As industries pivot towards sustainable practices, FRP valves emerge as a preferable choice due to their reduced carbon footprint during production and longer operational life that minimizes waste generation. Trust in FRP valves is bolstered by industry certifications and compliance with international standards. Manufacturers engage in rigorous testing processes to ensure that each product meets stringent performance metrics. Certifications from bodies such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide assurance to end-users about the quality and reliability of the valves. For professionals considering the integration of FRP valves into their systems, firsthand experiences and case studies are pivotal. Engineers report significant improvements in system performance and cost efficiency post-adoption of FRP valves. Feedback from plant supervisors and maintenance teams frequently highlights the decrease in unscheduled downtime and reduced frequency of part replacements, further reinforcing the trustworthiness and efficacy of these components. In conclusion, FRP valves are not merely an alternative to conventional options; they are a transformative force within industries sensitive to corrosion, weight, and durability challenges. Their extensive use in modern applications is prompted by their proven performance capabilities and substantial long-term economic benefits. As industries continually adapt to meet demanding operational standards and environmental considerations, FRP valves remain at the forefront as a reliable and authoritative option for fluid control needs.

Related Products