-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 06, 2025 05:27

Back to list

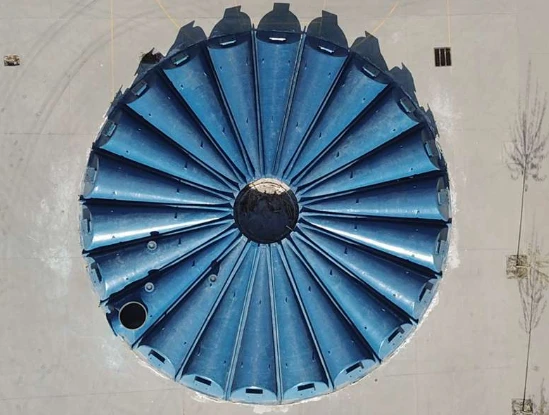

Gratings & Covers

FRP (Fiberglass Reinforced Plastic) valves have emerged as a preferred choice in various industries owing to their unique blend of durability, corrosion resistance, and lightweight properties. These characteristics make them indispensable in sectors such as chemical processing, oil and gas, and water treatment. The journey of an FRP valve from production to application unveils its profound influence on modern industrial operations, highlighting its pivotal role in maintaining operational efficiency and environmental sustainability.

From a sustainability perspective, FRP valves champion environmentally conscious engineering. The longevity and reduced maintenance demands of FRP valves translate to minimal environmental disturbance. By decreasing the need for constant replacements and the associated waste generation, industries employing FRP valves contribute positively to ecological conservation efforts. Furthermore, the energy efficiency gained through the use of FRP valves aligns with broader global initiatives focused on reducing carbon footprints and promoting sustainable practices. Innovation within the FRP valve market remains robust, driven by continuous advancements in polymer chemistry and fabrication techniques. These technological strides have led to the development of FRP valves with enhanced features such as improved resistance to extreme temperatures and pressures and advanced sealing mechanisms that mitigate leakage risks. As industries continue to leverage these advancements, the performance spectrum of FRP valves broadens, setting new benchmarks for reliability and operational excellence. Certifications and compliance also highlight the authoritative stance of FRP valves in industrial use. Recognized standards such as ISO and ASTM certifications provide a framework of trust, ensuring that FRP valves meet stringent quality and performance metrics. Companies incorporating certified FRP valves can operate with the assurance that their systems are supported by components that uphold industry-leading standards. In conclusion, the adoption of FRP valves signifies a strategic shift towards embracing cutting-edge materials science in pursuit of operational superiority and environmental stewardship. Their amalgamation of durability, efficiency, and sustainability underscores their integral role in modern industrial practices. For businesses evaluating valve options, the consideration of FRP valves is not merely about adopting a product but engaging with a material that embodies ingenuity, reliability, and forward-thinking engineering.

From a sustainability perspective, FRP valves champion environmentally conscious engineering. The longevity and reduced maintenance demands of FRP valves translate to minimal environmental disturbance. By decreasing the need for constant replacements and the associated waste generation, industries employing FRP valves contribute positively to ecological conservation efforts. Furthermore, the energy efficiency gained through the use of FRP valves aligns with broader global initiatives focused on reducing carbon footprints and promoting sustainable practices. Innovation within the FRP valve market remains robust, driven by continuous advancements in polymer chemistry and fabrication techniques. These technological strides have led to the development of FRP valves with enhanced features such as improved resistance to extreme temperatures and pressures and advanced sealing mechanisms that mitigate leakage risks. As industries continue to leverage these advancements, the performance spectrum of FRP valves broadens, setting new benchmarks for reliability and operational excellence. Certifications and compliance also highlight the authoritative stance of FRP valves in industrial use. Recognized standards such as ISO and ASTM certifications provide a framework of trust, ensuring that FRP valves meet stringent quality and performance metrics. Companies incorporating certified FRP valves can operate with the assurance that their systems are supported by components that uphold industry-leading standards. In conclusion, the adoption of FRP valves signifies a strategic shift towards embracing cutting-edge materials science in pursuit of operational superiority and environmental stewardship. Their amalgamation of durability, efficiency, and sustainability underscores their integral role in modern industrial practices. For businesses evaluating valve options, the consideration of FRP valves is not merely about adopting a product but engaging with a material that embodies ingenuity, reliability, and forward-thinking engineering.

Next:

Related Products