-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

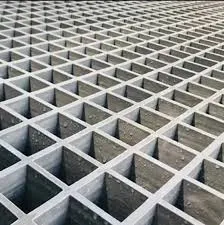

Exploring the Advantages of FRP Vessels in Modern Engineering Applications

The Rising Importance of FRP Vessels in Modern Industry

In today's rapidly evolving industrial landscape, the demand for durable and efficient materials has never been more critical. One of the frontrunners in this area is Fiber Reinforced Polymer (FRP) vessels. These vessels, crafted from composite materials that combine polymers with fibers, such as glass or carbon, have gained significant traction across various sectors due to their remarkable properties.

FRP vessels are celebrated for their lightweight and high strength, making them an ideal choice for applications where traditional materials may falter. Unlike steel or other metals, FRP does not corrode, a characteristic that has substantial implications for industries that rely on liquid storage, such as chemical processing and water treatment. In fact, the lifespan of FRP vessels can far exceed that of their metal counterparts, leading to lower maintenance costs and enhanced sustainability.

The Rising Importance of FRP Vessels in Modern Industry

Moreover, the manufacturing process for FRP vessels allows for greater design flexibility. Unlike traditional materials, FRP can be molded into complex shapes and sizes, catering to specific needs without the limitations often imposed by metalworking. This adaptability is particularly beneficial in applications ranging from aerospace to marine industries, where customized vessels can enhance performance and efficiency.

frp vessel

The thermal insulation properties of FRP vessels also contribute to their growing popularity. These vessels help maintain temperature control, which is crucial for industries such as food processing or pharmaceuticals, where temperature stability is essential. The insulation characteristics of FRP not only preserve product quality but also diminish energy costs, aligning with the global push towards more sustainable practices.

FRP vessels are increasingly used in the construction of tanks for storage, transportation, and processing. Their applications span numerous settings, including oil and gas, power generation, and wastewater treatment. The integration of FRP vessels can result in significant operational efficiencies, reduced environmental impact, and overall cost savings.

Despite the clear advantages, it is important to address some challenges associated with FRP vessels. Initial manufacturing costs can be higher compared to traditional materials, which can deter some companies from transitioning to this innovative solution. Furthermore, the recycling of FRP materials presents a complication, as their composite nature makes them less straightforward to recycle compared to metals.

However, advancements in material science are paving the way for potential solutions. Researchers are actively exploring methods to enhance the recyclability of FRP composites, which could further solidify the position of FRP vessels in the market. Additionally, the development of more cost-effective manufacturing techniques promises to lower barriers to entry, making FRP a more attractive option for various industries.

In conclusion, FRP vessels are carving out a distinct niche within contemporary industry. With their combination of strength, lightweight properties, and resistance to corrosion, they present a compelling alternative to traditional materials. As industries continue to seek out sustainable, efficient, and cost-effective solutions, the role of FRP vessels is likely to expand, making them a cornerstone of modern engineering and manufacturing practices. The future looks bright for FRP technology, ushering in a new era of innovation in materials science.