-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

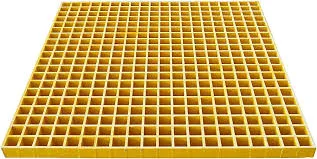

frp winding machine

The Evolution and Importance of FRP Winding Machines in Modern Manufacturing

Fibre Reinforced Plastic (FRP) winding machines are vital tools in the contemporary manufacturing landscape, especially for industries focused on producing composite materials. These machines automate the process of winding fibers around a core, which is essential in creating strong and lightweight structures used in various applications, including aerospace, automotive, and structural components.

The Evolution and Importance of FRP Winding Machines in Modern Manufacturing

One of the primary advantages of FRP winding machines is their ability to use various types of fibers, such as carbon, glass, and aramid. Each type of fiber offers different properties and performance characteristics. For instance, carbon fibers are renowned for their high strength and stiffness, making them ideal for aerospace applications, while glass fibers offer excellent durability and cost-effectiveness for general industrial uses. The versatility of FRP winding machines allows manufacturers to tailor products to meet specific engineering requirements.

frp winding machine

Moreover, these machines are equipped with advanced technology, including computer numerical control (CNC) systems, which enhance their precision and repeatability. Operators can program complex winding patterns and parameters, significantly reducing the risk of human error. This capability is particularly beneficial in producing intricate parts such as pressure vessels, pipes, and tanks, which require meticulous attention to detail in their construction.

In addition to improving product quality, FRP winding machines contribute to sustainability in manufacturing. By optimizing material usage and minimizing waste, these machines support eco-friendly practices. The lightweight nature of FRP materials also plays a pivotal role in reducing energy consumption in transportation and other applications.

In conclusion, FRP winding machines represent a significant advancement in manufacturing technology, offering increased efficiency, precision, and sustainability. As industries continue to demand lighter, stronger, and more durable materials, the importance of these machines will only grow, solidifying their role as a cornerstone in the production of advanced composite materials.