-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

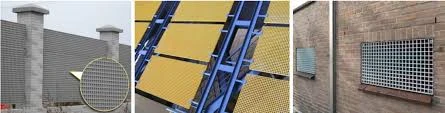

frp winding machine

Understanding FRP Winding Machines A Comprehensive Overview

Fiber Reinforced Plastic (FRP) winding machines play a crucial role in the manufacturing of composite materials, particularly in industries where strength-to-weight ratios are paramount. These machines utilize advanced winding techniques to produce cylindrical and other complex shapes from composite materials, making them essential in aerospace, automotive, marine, and construction sectors. This article delves into the significance of FRP winding machines, their operation, and their applications.

The Significance of FRP Winding Machines

FRP materials are known for their excellent mechanical properties, resistance to corrosion, and light weight. These attributes make FRP increasingly popular as an alternative to metal substances in various applications. The winding process is fundamental when producing FRP components as it allows the careful layering of fibers, ensuring optimal material performance. The machine’s precision is vital, as even minute variations in fiber alignment can lead to significant differences in strength and durability.

How FRP Winding Machines Operate

At the core of FRP winding machines is their ability to automate the winding process. A typical machine consists of several key components a spool for the fiber, a resin system, a mandrel (the shape around which materials are wound), and a control system. The winding process begins with the selection of appropriate fibers (such as carbon or glass) and a resin that will bond these fibers together.

The fiber is pulled from a spool and guided onto a rotating mandrel. The machine can adjust the tension and speed of the fiber to ensure a consistent application. As the mandrel spins, the operator can control the angle of winding, which is critical for achieving the desired mechanical properties. Once the fibers are laid down, a curing process typically follows, which hardens the resin and fuses the fibers together, forming a rigid structure.

Modern FRP winding machines are equipped with advanced control systems, allowing for precise adjustments and monitoring throughout the winding process. This increases efficiency and ensures that the final products meet design specifications.

Applications of FRP Winding Machines

frp winding machine

The applications of FRP winding machines are diverse and continually expanding as technological advancements are made. Some common areas where these machines are used include

1. Aerospace Components The aerospace industry utilizes FRP for components like fuel tanks and fuselage structures, where lightweight and high strength are critical.

2. Automotive Parts Many manufacturers are turning to FRP for producing parts such as driveshafts, chassis components, and body panels to enhance fuel efficiency without sacrificing performance.

3. Marine Applications FRP is ideal for boat hulls and components due to its resistance to water and chemicals, leading to longer-lasting and lower-maintenance vessels.

4. Wind Energy In wind turbine construction, FRP winding machines are used to manufacture blades that need to be both strong and lightweight for optimal energy capture.

5. Construction Materials In the construction field, FRP is utilized for reinforcing structures, bridges, and other settings, where its resistance to environmental factors is beneficial.

Conclusion

In conclusion, FRP winding machines are instrumental in the production of advanced composite materials that are transforming various industries by offering lightweight and durable solutions. As technologies evolve, the efficiency and capabilities of these machines will continue to improve, leading to enhanced applications and innovations in the field of materials engineering. Understanding and leveraging the capabilities of FRP winding machines is vital for companies looking to gain a competitive edge in materials manufacturing. With their growing importance, the future of FRP technology remains bright and full of potential.