-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 28, 2025 04:38

Back to list

Car and Boat Body

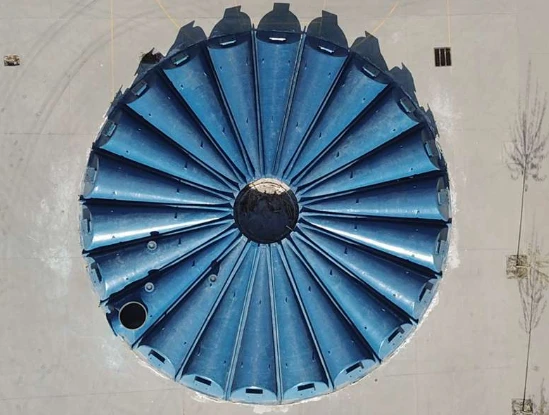

The fiberglass reinforced plastic (FRP) winding machine is revolutionizing the manufacturing industry with its exceptional capacity to create highly durable and reliable FRP pipes, tanks, and vessels. This state-of-the-art equipment has quickly become an indispensable tool for manufacturers worldwide, merging cutting-edge technology with unparalleled precision.

The authoritativeness of FRP winding machines is further backed by their widespread adoption and endorsement by industry leaders. Prominent manufacturers and engineering firms often reference these machines in technical papers and industrial showcases, underscoring their pivotal role in modern manufacturing practices. Numerous case studies and peer-reviewed articles attest to the machines' capability to reduce material wastage and improve product consistency, solidifying their authoritative status in industrial circles. Trustworthiness is perhaps the most compelling feature of FRP winding machines. The reliability and durability of the products they manufacture have been rigorously tested over the years. Long-term studies examining FRP products—including pipes and tanks—consistently find that those produced by winding machines exhibit exceptional longevity and resilience against stress and environmental factors. Feedback from industrial clients often highlights the peace of mind these machines provide, knowing that the end products can endure decades of service with minimal maintenance. In conclusion, FRP winding machines are more than just tools; they are the cornerstone of modern, efficient, and sustainable manufacturing. Their sophisticated design, endorsed by extensive industry experience and backed by a robust body of technical expertise, makes them the preferred choice for manufacturers required to deliver high-quality, durable FRP components. Trust in these machines is continuously renewed as they deliver consistency and reliability in every application, affirming their stature as indispensable assets in any production line.

The authoritativeness of FRP winding machines is further backed by their widespread adoption and endorsement by industry leaders. Prominent manufacturers and engineering firms often reference these machines in technical papers and industrial showcases, underscoring their pivotal role in modern manufacturing practices. Numerous case studies and peer-reviewed articles attest to the machines' capability to reduce material wastage and improve product consistency, solidifying their authoritative status in industrial circles. Trustworthiness is perhaps the most compelling feature of FRP winding machines. The reliability and durability of the products they manufacture have been rigorously tested over the years. Long-term studies examining FRP products—including pipes and tanks—consistently find that those produced by winding machines exhibit exceptional longevity and resilience against stress and environmental factors. Feedback from industrial clients often highlights the peace of mind these machines provide, knowing that the end products can endure decades of service with minimal maintenance. In conclusion, FRP winding machines are more than just tools; they are the cornerstone of modern, efficient, and sustainable manufacturing. Their sophisticated design, endorsed by extensive industry experience and backed by a robust body of technical expertise, makes them the preferred choice for manufacturers required to deliver high-quality, durable FRP components. Trust in these machines is continuously renewed as they deliver consistency and reliability in every application, affirming their stature as indispensable assets in any production line.

Next:

Related Products