-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

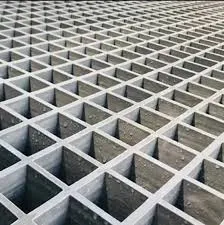

Innovative Glass Fiber Tanks for Enhanced Durability and Performance in Various Applications

The Advancements and Applications of Glass Fiber Tanks

Glass fiber tanks, often referred to as fiberglass tanks, have emerged as a crucial component in various industries due to their unique properties and advantages. The use of fiberglass reinforced plastic (FRP) technology has transformed the way we approach the storage and transportation of a multitude of substances, ranging from water to chemicals. This article delves into the construction, benefits, applications, and future of glass fiber tanks.

Construction and Characteristics

Glass fiber tanks are manufactured using a combination of glass fibers and resin, which results in a strong, lightweight, and corrosion-resistant product. The process typically involves layering glass fibers in a mold and saturating them with resin, which is then cured to create a solid structure. This construction method not only enhances the durability of the tanks but also allows for customization in size and shape to suit specific storage needs.

One of the key characteristics of glass fiber tanks is their resistance to corrosion. Unlike traditional metal tanks, which can rust and degrade over time when exposed to various chemicals, fiberglass offers a stable solution that withstands harsh environments. Additionally, these tanks are less prone to leaks, which minimizes environmental risks and contamination.

Benefits of Glass Fiber Tanks

The advantages of glass fiber tanks make them a popular choice across industries. Firstly, their lightweight nature makes transportation and installation easier, reducing labor costs and the time required for setup. Unlike concrete or metal tanks, fiberglass tanks do not require extensive foundation work, allowing for flexibility in placement.

Another benefit is their excellent thermal insulation properties. This is particularly important for tanks storing temperature-sensitive materials. The insulation helps to maintain the desired temperature of the contents, thereby ensuring optimal functionality.

Moreover, fiberglass tanks have a longer lifespan compared to traditional alternatives. With proper maintenance, they can last for several decades without significant deterioration. This longevity translates to reduced replacement costs and waste, making them a more sustainable option in the long run.

Applications of Glass Fiber Tanks

glass fiber tank

The versatility of glass fiber tanks allows them to be used in a wide range of applications. One of the most common uses is in the storage of water, both for municipal systems and agricultural purposes. Farmers utilize fiberglass tanks for irrigation and chemical storage, as they can safely hold fertilizers and pesticides without the risk of corrosion.

In the industrial sector, glass fiber tanks are utilized for chemical storage, wastewater treatment, and in oil and gas applications. Their ability to resist a wide array of corrosive substances makes them ideal for storing acids, bases, and other reactive materials. Many industries have recognized the importance of safety and sustainability, leading to a growing preference for fiberglass solutions.

The food and beverage industry also benefits from glass fiber tanks. These tanks are used for fermenting, brewing, and storing various food products. The non-reactive nature of fiberglass ensures that there is no contamination of flavors or substances, making them an optimal choice for food storage.

Future of Glass Fiber Tanks

As industries continue to evolve, so too does the technology surrounding glass fiber tanks. The future looks promising, with several innovations on the horizon. Advances in resin formulations are expected to enhance the performance of fiberglass tanks, providing even greater resistance to extreme temperatures and corrosive environments.

Additionally, the growing emphasis on sustainability may pave the way for more eco-friendly production methods. Researchers are exploring bio-based resins and recyclable materials to reduce the environmental impact of fiberglass manufacturing. This aligns with global initiatives aimed at decreasing waste and promoting circular economy practices.

Furthermore, the integration of smart technology could revolutionize the way glass fiber tanks are monitored and maintained. Sensors can be embedded within the structure to track temperature, pressure, and chemical composition in real-time, providing invaluable data that can prevent potential issues before they arise.

Conclusion

Glass fiber tanks represent a significant advancement in storage solutions, characterized by their durability, corrosion-resistance, and versatility. As industries strive for more efficient, safe, and sustainable practices, the demand for fiberglass tanks will undoubtedly continue to grow. Embracing the innovations in this field will not only enhance operational efficiency but also contribute to a more sustainable future for various sectors. Whether for water management, chemical storage, or food processing, glass fiber tanks are poised to play a pivotal role in meeting the challenges of tomorrow.