-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

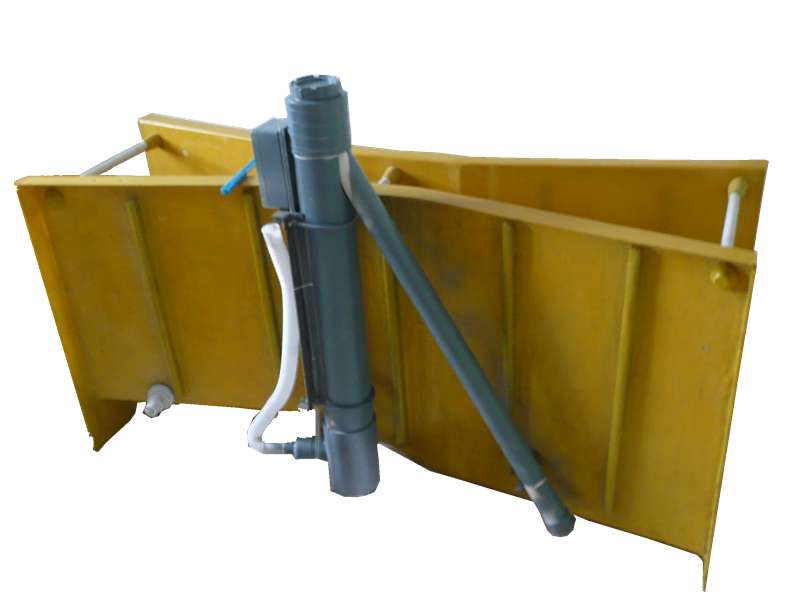

grp dual lamination product

A Comprehensive Overview of GRP Dual Lamination Products

The advancement of material science has led to the development of innovative products that cater to various industrial needs. One such breakthrough is the GRP (Glass Reinforced Plastic) dual lamination product, which has gained significant popularity in recent years due to its unique properties and wide range of applications. This article explores the characteristics, benefits, and uses of GRP dual lamination products, highlighting their importance in modern industries.

GRP dual lamination combines the robust characteristics of glass fiber reinforced plastic with an additional layer of protection, enhancing its durability and performance. This dual approach involves layering a special resin matrix infused with glass fibers over a base material, which can be aluminum, steel, or even another composite. The result is a product that boasts exceptional strength, lightweight properties, and enhanced resistance to environmental factors such as moisture, chemicals, and UV radiation.

A Comprehensive Overview of GRP Dual Lamination Products

Furthermore, the dual lamination process provides an extra layer of protection against corrosive elements, making GRP products ideal for harsh environments. For instance, in the oil and gas industry, where equipment is often exposed to corrosive substances, the use of GRP dual lamination can lead to significant cost savings by reducing maintenance and replacement needs. Similarly, in marine applications, these products are less prone to degradation, ensuring longevity and safety.

grp dual lamination product

In addition to its robust physical properties, GRP dual lamination products also offer versatility in design and application. They can be molded into various shapes and sizes, catering to specific operational needs. The ability to customize these products means manufacturers can create tailored solutions that best suit their projects, enhancing functionality and aesthetic appeal.

Moreover, the manufacturing process of GRP dual lamination products often incorporates advanced technologies such as automated lamination techniques, which ensure consistency and high-quality finishes. This technology not only reduces production times but also minimizes labor costs, leading to more economically viable products for manufacturers and end-users alike.

It's also worth noting that GRP products are environmentally friendly. With an increasing focus on sustainable practices, the dual lamination process allows for the use of recyclable materials and resins that have lower environmental impact. This makes GRP a suitable choice for industries striving to meet sustainability goals while still requiring high-performance materials.

In conclusion, GRP dual lamination products represent a significant advancement in material technology, offering numerous advantages across various sectors. Their unique combination of strength, lightweight properties, corrosion resistance, and design versatility positions them as indispensable components in modern manufacturing and construction. As industries continue to evolve, the demand for innovative materials like GRP dual lamination is expected to grow, paving the way for new applications and technologies that further enhance performance and sustainability.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025