-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

grp chemical product

Understanding GRP Chemical Products A Comprehensive Overview

Glass Reinforced Plastic (GRP) is a unique composite material widely used in various industries due to its lightweight, strength, and corrosion-resistant properties. GRP is composed of a polymer matrix reinforced with glass fibers, resulting in a material that offers both durability and flexibility. This article aims to provide a comprehensive overview of GRP chemical products, covering their composition, applications, benefits, and considerations.

Composition of GRP

At its core, GRP consists of two main components the polymer matrix and the glass fibers. The polymer matrix is typically made from a thermosetting resin, such as unsaturated polyester, epoxy, or vinyl ester. These resins provide the foundation for the composite, imparting essential properties such as resistance to heat and chemical degradation. The glass fibers, on the other hand, are responsible for enhancing the mechanical strength and structural integrity of GRP products. These fibers can be woven or chopped, depending on the desired characteristics of the final product.

Applications of GRP Chemical Products

GRP chemical products find applications in several sectors, thanks to their impressive performance characteristics. Some notable applications include

1. Construction and Architecture In the construction industry, GRP is used for roofing, facades, and structural elements. Its lightweight nature reduces load-bearing requirements, leading to more efficient designs. Additionally, GRP can be molded into complex shapes, allowing for innovative architectural designs.

2. Transportation The automotive and aerospace industries have embraced GRP for components such as body panels, interior parts, and structural components. The material's lightweight nature contributes to improved fuel efficiency, while its strength ensures safety.

3. Marine Industry GRP is widely used in the manufacturing of boats and yachts due to its water-resistant properties. The material does not corrode like metals, making it suitable for prolonged exposure to harsh marine environments.

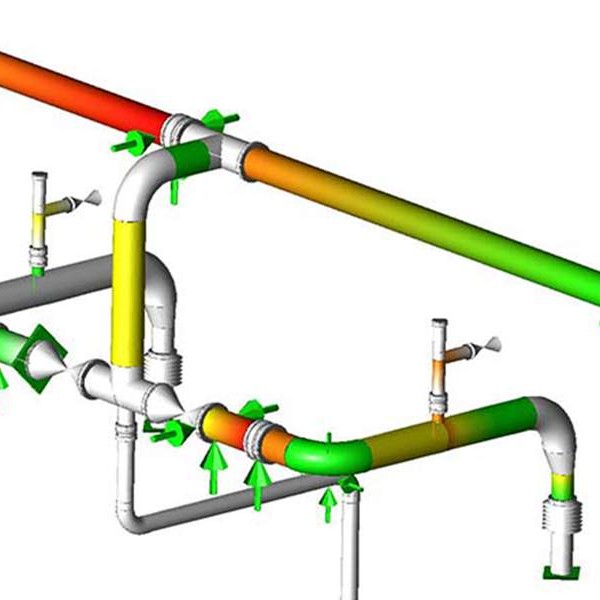

4. Chemical Storage Tanks and Piping GRP's outstanding resistance to various chemicals makes it an ideal choice for chemical storage tanks and piping systems. Industries that handle corrosive substances often rely on GRP to ensure safety and longevity.

5. Sports Equipment and Consumer Goods GRP is used in the production of sporting goods, such as surfboards and bicycles, due to its ability to withstand significant wear and tear. Its lightweight characteristic also promotes performance enhancement in competitive sports.

grp chemical product

Benefits of GRP Chemical Products

The popularity of GRP chemical products can be attributed to several key benefits

- Durability GRP products exhibit excellent resistance to environmental factors, chemicals, and UV radiation, resulting in a long service life.

- Lightweight Compared to traditional materials like metal or wood, GRP is much lighter, offering significant advantages in application where weight reduction is critical.

- Cost-Effective Though the initial investment may be higher, the longevity and low maintenance requirements of GRP products can lead to cost savings over time.

- Versatility GRP can be molded into various shapes and sizes, allowing for customized solutions that meet specific needs.

Considerations and Challenges

While GRP offers many advantages, there are certain challenges to consider. The manufacturing process requires skilled labor and specialized equipment, which can drive up costs. Additionally, disposal and recycling of GRP products can pose environmental challenges, as they cannot be easily broken down compared to traditional materials.

Conclusion

In conclusion, GRP chemical products are a vital component in modern manufacturing and construction, providing solutions that are both innovative and efficient. With a diverse range of applications across industries, the benefits of durability, lightweight, and versatility make GLP an attractive choice for businesses looking to enhance their product offerings. However, it is essential to address the challenges associated with production and disposal to ensure a sustainable future for this promising material. As industries continue to evolve, the demand for GRP chemical products is likely to grow, driving further research and development in this fascinating field.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025