-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 15, 2025 04:50

Back to list

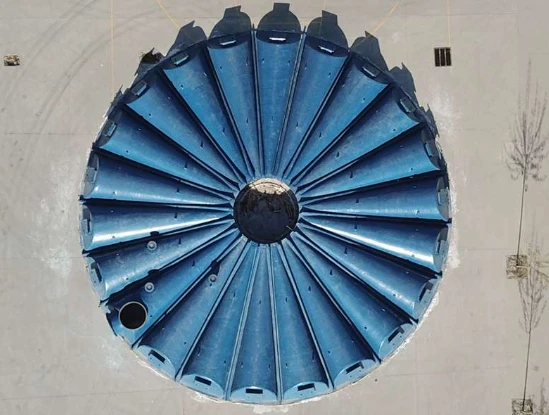

grp clarifier

The Growth and Potential of GRP Clarifiers in Industrial Applications

In terms of expertise, the production and installation of GRP clarifiers require specialized knowledge and skills. It's important to partner with manufacturers who have a proven track record in developing and implementing these systems. The manufacturing process involves precise layering techniques and stringent quality control measures to ensure the end product meets the demanding standards of industrial applications. Engineers and technicians should be trained to work with this material, emphasizing the importance of knowledge transfer in the industry. Trust in GRP clarifiers is growing, backed by numerous case studies and real-world applications that demonstrate their reliability. In sectors such as mining, chemical processing, and municipal water treatment, GRP clarifiers have consistently provided robust performance under strenuous conditions. Their growing acceptance is also due to the industry's recognition of the long-term cost benefits they offer. While initial outlay could be slightly higher than traditional materials, the lifecycle maintenance and operational savings significantly outweigh initial expenditures. Authoritativeness in this domain is bolstered by the ongoing research and technological advancements surrounding GRP materials. Institutions and industry bodies regularly publish studies and findings that highlight improvements and new applications for GRP products. Engineers and decision-makers can rely on these resources to make informed choices, ensuring that they are implementing state-of-the-art solutions in their facilities. As industries continue to prioritize sustainability, the environmental benefits of GRP clarifiers cannot be overstated. They require less energy to produce compared to metals, and their extended lifespan reduces the frequency of replacements, thereby minimizing waste. For organizations aiming to enhance their green credentials, adopting GRP technologies is a strategic move. In conclusion, the future of industrial clarifiers is undoubtedly leaning towards GRP solutions. Their resilience, cost-effectiveness, and versatility provide substantial advantages over traditional materials. Industry professionals who embrace this technology will likely see enhanced operational efficiencies and contribute positively to environmental sustainability. As GRP clarifiers gain more prominence, it is crucial for industry stakeholders to remain updated on developments and leverage these advanced systems to remain competitive in an ever-evolving industrial landscape.

In terms of expertise, the production and installation of GRP clarifiers require specialized knowledge and skills. It's important to partner with manufacturers who have a proven track record in developing and implementing these systems. The manufacturing process involves precise layering techniques and stringent quality control measures to ensure the end product meets the demanding standards of industrial applications. Engineers and technicians should be trained to work with this material, emphasizing the importance of knowledge transfer in the industry. Trust in GRP clarifiers is growing, backed by numerous case studies and real-world applications that demonstrate their reliability. In sectors such as mining, chemical processing, and municipal water treatment, GRP clarifiers have consistently provided robust performance under strenuous conditions. Their growing acceptance is also due to the industry's recognition of the long-term cost benefits they offer. While initial outlay could be slightly higher than traditional materials, the lifecycle maintenance and operational savings significantly outweigh initial expenditures. Authoritativeness in this domain is bolstered by the ongoing research and technological advancements surrounding GRP materials. Institutions and industry bodies regularly publish studies and findings that highlight improvements and new applications for GRP products. Engineers and decision-makers can rely on these resources to make informed choices, ensuring that they are implementing state-of-the-art solutions in their facilities. As industries continue to prioritize sustainability, the environmental benefits of GRP clarifiers cannot be overstated. They require less energy to produce compared to metals, and their extended lifespan reduces the frequency of replacements, thereby minimizing waste. For organizations aiming to enhance their green credentials, adopting GRP technologies is a strategic move. In conclusion, the future of industrial clarifiers is undoubtedly leaning towards GRP solutions. Their resilience, cost-effectiveness, and versatility provide substantial advantages over traditional materials. Industry professionals who embrace this technology will likely see enhanced operational efficiencies and contribute positively to environmental sustainability. As GRP clarifiers gain more prominence, it is crucial for industry stakeholders to remain updated on developments and leverage these advanced systems to remain competitive in an ever-evolving industrial landscape.

Next:

Related Products