-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

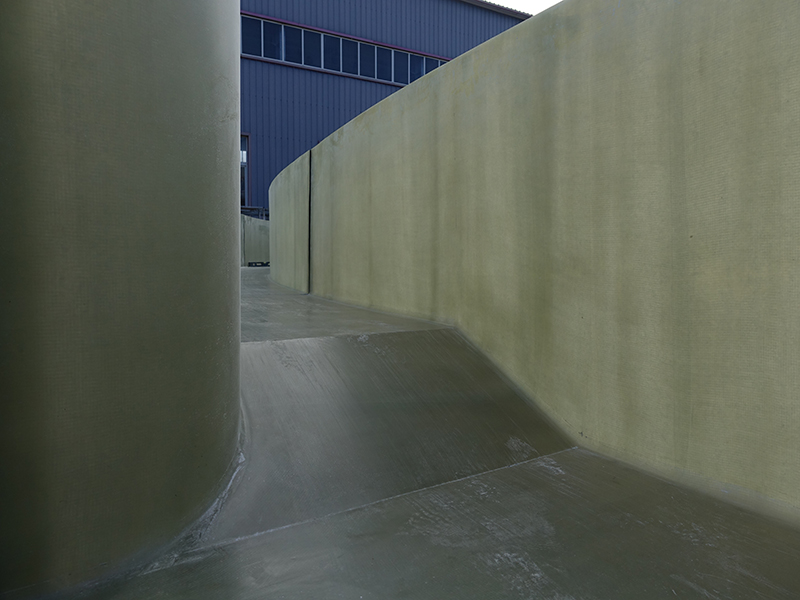

Creating a Cover Design Inspired by grp Elements and Trends

Understanding GRP Cover A Comprehensive Overview

Glass Reinforced Plastic (GRP), also known as fiberglass, is a composite material that has gained immense popularity in various industries due to its unique properties, including high strength-to-weight ratio, corrosion resistance, and versatility. GRP cover refers to the protective layer made from this composite material, commonly used in a variety of applications ranging from automotive parts to building materials and even yacht construction. This article delves into the significance of GRP covers, their applications, advantages, and future trends.

Applications of GRP Covers

GRP covers are widely utilized across several sectors. In the construction industry, GRP is used for roofing systems, cladding, and skylights. Its lightweight nature and resistance to harsh weather conditions make it a favorable option for modern buildings. Moreover, GRP covers are employed in wastewater treatment facilities, as they can withstand chemical exposure and reduce maintenance costs.

In the automotive sector, GRP is used to manufacture body parts, panels, and components that require durability without adding excessive weight. The aerospace industry has also recognized the benefits of GRP, utilizing it in the production of lightweight components that can enhance fuel efficiency and operational performance.

Marine applications are among the most notable uses of GRP. GRP covers are extensively used in the construction of boats, yachts, and other watercraft due to their buoyancy and resistance to saltwater corrosion. The lightweight yet durable nature of GRP makes it ideal for hulls, decks, and other structural components.

Advantages of GRP Covers

The benefits of GRP covers are manifold. Firstly, their lightweight composition contributes to easier handling and transportation, reducing overall installation costs. Secondly, GRP is known for its exceptional strength and rigidity, allowing it to withstand significant stress without deformation. This property is particularly important in applications where structural integrity is paramount.

grp cover

Another advantage is GRP's resistance to environmental factors such as moisture, UV radiation, and chemicals. This intrinsic resistance reduces the likelihood of degradation over time, leading to lower maintenance costs and extended lifespans for products made from GRP. Additionally, the versatility in design and color allows for customization, enabling designers to create aesthetically pleasing and functional products.

Moreover, GRP is a cost-effective material choice due to its long-term durability and the reduced need for repairs or replacements. This has made it an attractive option for businesses looking to optimize their budgets while maintaining quality.

Future Trends in GRP Technology

As industries continue to evolve, so does the technology surrounding GRP. Innovations in manufacturing processes, such as automated fiber placement and 3D printing, are enabling more efficient production of GRP covers. These advancements not only reduce production time but also enhance the precision and integrity of the final products.

Sustainability is also becoming a crucial concern in material selection. Research into biodegradable composites and recycling methods for existing GRP products is gaining momentum. This shift towards eco-friendly practices aligns with global initiatives aimed at reducing waste and promoting sustainable manufacturing.

Conclusion

In summary, GRP covers represent a significant advancement in material engineering, providing a robust, lightweight, and durable solution for various applications. Their undeniable advantages, coupled with ongoing innovations and a commitment to sustainability, suggest a bright future for GRP technology. As industries continue to embrace this composite material, it’s clear that GRP covers will play an integral role in shaping the future of manufacturing and construction.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025