-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 15, 2025 05:51

Back to list

Ship Pipings and Fittings

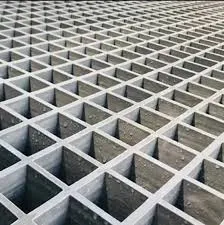

Exploring the Future of Vibration Control with GRP Dampers

Automotive engineers also place considerable trust in GRP dampers, especially in the design of electric vehicles (EVs). The silent operation of EVs makes them more susceptible to discernible vibrations, which can impact both performance and passenger comfort. GRP dampers provide a solution by minimizing these unwanted vibrations, ensuring a smoother and quieter ride. From a scientific perspective, the research into GRP as a damping material underscores its effectiveness. Studies have highlighted its ability to maintain performance over extended periods, even under substantial stress and strain. This reliability is crucial for sectors like construction, where environmental conditions can be unpredictable. The thermal properties of GRP also contribute to its popularity. Unlike some metals, which can expand and contract significantly with temperature variations, GRP maintains its shape and effectiveness. This thermal stability ensures consistent performance, an essential quality for structures exposed to fluctuating temperatures. The adoption of GRP dampers is also a testament to the industry's shift towards more sustainable and eco-friendly solutions. Traditional dampers often necessitate the use of resources that are scarce or environmentally taxing to extract and produce. In contrast, GRP, made from readily available materials, represents a more sustainable choice. Its durability and long lifecycle further reduce the environmental impact, aligning with modern green engineering practices. In essence, the development and implementation of GRP dampers signify a pivotal point in vibration control technology. These dampers not only provide superior performance and durability but also represent an advancement toward more sustainable industrial practices. As industries continue to evolve and the demands for high-performance, lightweight, and reliable solutions grow, GRP dampers are poised to play an increasingly vital role. For decision-makers, engineers, and architects considering the next generation of vibration control solutions, the experience and research surrounding GRP dampers provide a compelling case. Their proven expertise and reliability render them an authoritative choice, ensuring that structures and machines can meet today's rigorous standards of safety and efficiency. In this rapidly progressing field, GRP dampers are not just an innovation but a necessity, demonstrating a trustworthy advancement in combating the complexities of vibration-related challenges.

Automotive engineers also place considerable trust in GRP dampers, especially in the design of electric vehicles (EVs). The silent operation of EVs makes them more susceptible to discernible vibrations, which can impact both performance and passenger comfort. GRP dampers provide a solution by minimizing these unwanted vibrations, ensuring a smoother and quieter ride. From a scientific perspective, the research into GRP as a damping material underscores its effectiveness. Studies have highlighted its ability to maintain performance over extended periods, even under substantial stress and strain. This reliability is crucial for sectors like construction, where environmental conditions can be unpredictable. The thermal properties of GRP also contribute to its popularity. Unlike some metals, which can expand and contract significantly with temperature variations, GRP maintains its shape and effectiveness. This thermal stability ensures consistent performance, an essential quality for structures exposed to fluctuating temperatures. The adoption of GRP dampers is also a testament to the industry's shift towards more sustainable and eco-friendly solutions. Traditional dampers often necessitate the use of resources that are scarce or environmentally taxing to extract and produce. In contrast, GRP, made from readily available materials, represents a more sustainable choice. Its durability and long lifecycle further reduce the environmental impact, aligning with modern green engineering practices. In essence, the development and implementation of GRP dampers signify a pivotal point in vibration control technology. These dampers not only provide superior performance and durability but also represent an advancement toward more sustainable industrial practices. As industries continue to evolve and the demands for high-performance, lightweight, and reliable solutions grow, GRP dampers are poised to play an increasingly vital role. For decision-makers, engineers, and architects considering the next generation of vibration control solutions, the experience and research surrounding GRP dampers provide a compelling case. Their proven expertise and reliability render them an authoritative choice, ensuring that structures and machines can meet today's rigorous standards of safety and efficiency. In this rapidly progressing field, GRP dampers are not just an innovation but a necessity, demonstrating a trustworthy advancement in combating the complexities of vibration-related challenges.

Next:

Related Products