-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

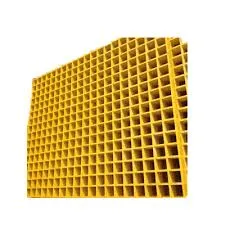

grp demister

Understanding GRP Demisters Efficiency in Vapor Liquid Separation

In industrial applications, the management of vapor and liquid separation plays a critical role in optimizing processes, ensuring safety, and enhancing the efficiency of operations. One innovative solution that has gained popularity in various sectors is the Glass Reinforced Plastic (GRP) demister. This article delves into the concept, advantages, and applications of GRP demisters, shedding light on their significance in modern industrial processes.

What is a GRP Demister?

A GRP demister is a device designed to remove moisture from vapor streams, typically found in processes like gas separation, air conditioning, and chemical manufacturing. The demister operates by using a combination of physical principles to enhance the separation of liquid droplets from gases. The GRP material provides structural strength, durability, and chemical resistance, making it an ideal choice for diverse environments.

Structural integrity is vital in applications where chemical exposure is prevalent, and GRP demisters stand out due to their resistance to corrosion, thus ensuring longevity. The way these demisters function revolves around the principles of inertia and surface tension, leading to effective liquid droplet coalescence and subsequent removal.

How Does It Work?

The thermodynamic properties of vapor and liquid are inherently different, which allows for effective separation. When gas containing moisture passes through the GRP demister, the design intricacies of the demister encourage the tiny liquid droplets to collide and coalesce into larger droplets. Once large enough, these droplets are acted upon by gravity, causing them to fall into a collection tank or drain.

The design of GRP demisters often includes various types of packing materials, which increase the surface area and enhance the chances of droplet coalescence. The demister is strategically placed in the gas stream to maximize contact time between the vapor and the packing material, resulting in an efficient separation process.

Advantages of GRP Demisters

1. Corrosion Resistance One of the standout features of GRP is its resistance to corrosive chemicals. In industries dealing with aggressive substances, GRP demisters offer a longer service life compared to traditional materials, which can be susceptible to degradation over time.

grp demister

2. Lightweight and Easy Installation Compared to metal alternatives, GRP is significantly lighter, which simplifies the installation process and reduces structural support requirements. This attribute can lead to lower overall project costs and faster setup times.

3. Cost-Effectiveness The initial investment in a GRP demister may be higher than some conventional options; however, the long-term savings on maintenance, repairs, and replacements often justify the expense.

4. High Efficiency Due to the unique design and superior material properties, GRP demisters operate with high efficiency, reducing the amount of liquid carryover in gas streams.

5. Customizability GRP demisters can be tailored to meet specific operational needs, such as size, shape, and packing type, ensuring that they fit seamlessly into various industrial applications.

Applications of GRP Demisters

The applicability of GRP demisters spans numerous industries. In petrochemical processes, they serve to capture hydrocarbons from vapor streams, improving air quality and compliance with environmental regulations. In water and wastewater treatment facilities, they assist in removing moisture from biogas produced during sewage treatment.

Moreover, in pharmaceutical manufacturing, where cleanliness and precision are crucial, GRP demisters ensure that vapor streams are devoid of any liquid particles, delivering pure air to sensitive processes.

Conclusion

In conclusion, GRP demisters represent a significant advancement in the realm of vapor-liquid separation technologies. Their unique properties, coupled with a robust operational mechanism, enable industries to achieve high efficiency, reduce environmental impact, and enhance process reliability. As industries continue to pursue better ways to manage vapor and liquid separation, GRP demisters will undoubtedly play a pivotal role in shaping the future of industrial operations. By leveraging the benefits of these innovative devices, companies can not only maximize their productivity but also contribute to a greener, more sustainable future.