-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

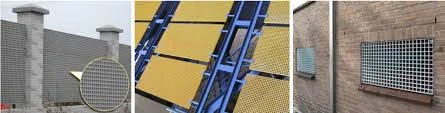

High Efficiency GRP Demisters for Superior Air and Liquid Separation Solutions

Understanding GRP Demisters Enhancing Efficiency in Industrial Processes

In many industrial applications, the separation of liquid droplets from gas streams is a critical process. Enter the GRP demister, an efficient device designed to separate these droplets effectively using glass-reinforced plastic (GRP) materials. This article explores the functionality, benefits, and applications of GRP demisters, highlighting their importance in various industrial sectors.

What is a GRP Demister?

A GRP demister is a type of mist eliminator that operates using a series of coalescing stages to capture and separate liquid droplets from gas streams. It is typically installed in gas handling systems where droplet formation is prevalent, such as in scrubbers, dryers, and exhaust systems. The primary aim of a GRP demister is to improve the quality of the gas discharge and to recover valuable liquids.

The construction of a GRP demister involves the use of glass-reinforced plastic, which provides high resistance to chemical corrosion, high strength-to-weight ratio, and excellent durability. This makes GRP demisters suitable for applications where harsh operating conditions exist, including those involving aggressive chemicals and high temperatures.

How Does a GRP Demister Work?

The demisting process begins when the contaminated gas stream enters the demister unit. As the gas flows through a series of specially designed elements, liquid droplets collide with the surfaces of these elements and merge. The design of GRP demisters ensures that the gas velocity is optimized to facilitate this coalescence process.

Once the droplets merge, they grow larger and gravitate toward the bottom of the demister unit due to gravity. The clean gas is then allowed to pass through the top outlet, effectively removing the liquid contaminants. This simple yet efficient mechanism makes GRP demisters a vital component in various industrial applications.

Benefits of GRP Demisters

grp demister

1. Corrosion Resistance One of the most significant advantages of GRP demisters is their high resistance to corrosive substances. This attribute allows them to be used in diverse industries, including chemical processing and wastewater treatment, where corrosion can lead to reduced equipment lifespan and increased maintenance costs.

2. Lightweight and Strong Compared to traditional metal demisters, GRP demisters offer a lighter alternative without compromising on strength. This lightweight nature facilitates easier installation and reduces the overall handling costs.

3. Improved Efficiency The unique design of the GRP demister enhances the coalescing effect, resulting in higher separation efficiency. This leads to cleaner gas streams and reduced environmental impact, aligning with modern mandates for sustainability and eco-friendliness in industrial operations.

4. Cost-Effective The longevity and reduced maintenance requirements of GRP demisters contribute to overall cost savings. Industries can benefit from lower replacement rates while ensuring the consistent performance of their gas handling systems.

Applications of GRP Demisters

GRP demisters find applications across a broad range of industries. In petrochemical facilities, for instance, they are employed to prevent liquid hydrocarbon carryover in gas streams. In the food and beverage sector, these devices help safeguard product purity by removing undesired liquids in gas processes, such as in breweries where steam is used.

Moreover, GRP demisters are utilized in HVAC systems to improve air quality by removing mist and entrained droplets from the air, thus enhancing operational efficiency while ensuring that moisture does not lead to mold or corrosion.

Conclusion

The GRP demister represents a significant advancement in gas-liquid separation technology. With its robust design and excellent performance characteristics, it provides industries with a reliable solution to achieve cleaner gas emissions and recycle valuable liquids. As industrial processes continue to evolve, implementing efficient and durable solutions like GRP demisters will be critical in addressing the challenges of environmental impact and operational efficiency. Investing in such technology is not only beneficial for business operations but is also vital for promoting sustainability across industrial sectors.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025