-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

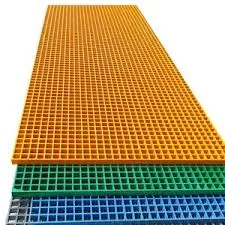

grp dual lamination product

Exploring GRP Dual Lamination Products A Comprehensive Overview

In today's fast-paced industrial landscape, the need for innovative and durable materials has become paramount. Among the various options available, Glass Reinforced Plastic (GRP) dual lamination products have emerged as a popular choice due to their exceptional properties and versatility. This article explores the key features, advantages, and applications of GRP dual lamination products, highlighting their importance in various industries.

What is GRP Dual Lamination?

GRP dual lamination refers to a manufacturing process that involves layering glass fiber reinforced plastic with another material, typically a thermoplastic or another composite. This dual-layer approach enhances the mechanical properties of the base material while providing improved resistance to environmental factors such as corrosion, impact, and UV radiation. The result is a robust, lightweight product that offers enhanced performance over traditional materials.

Key Features

1. Durability One of the standout characteristics of GRP dual lamination products is their exceptional durability. The combination of glass fibers and plastic results in a material that can withstand harsh conditions, making it ideal for outdoor applications and settings exposed to chemical agents.

2. Lightweight Compared to metals and other heavy materials, GRP is significantly lighter, which can lead to reduced transportation costs and easier installation. This lightweight nature also contributes to greater energy efficiency in applications such as transportation and construction.

3. Customization GRP dual lamination products can be tailored to meet specific requirements. Manufacturers can adjust parameters such as thickness, fiber orientation, and materials used to cater to the desired mechanical and aesthetic properties.

4. Corrosion Resistance One of the critical advantages of GRP products is their intrinsic resistance to corrosion. This feature is particularly valuable in industries such as chemical processing and oil & gas, where materials are often exposed to aggressive substances.

5. Thermal and Electrical Insulation GRP dual lamination products provide excellent thermal and electrical insulation, making them suitable for applications in electronics and power distribution systems.

grp dual lamination product

Applications

The versatility of GRP dual lamination products enables their use across a wide range of industries

- Construction GRP laminates are utilized in building facades, roofing systems, and structural components due to their lightweight and durable nature.

- Aerospace The aerospace sector benefits from the high strength-to-weight ratio of GRP, making it an ideal choice for various structural elements in aircraft.

- Transport The automotive and rail industries utilize GRP dual lamination for components such as body panels, hoods, and interior parts, enhancing both performance and fuel efficiency.

- Chemical and Oil & Gas Industries The resistance to corrosive substances makes GRP products a preferred choice for storage tanks, pipelines, and fittings.

- Marine Applications Boats and other marine structures benefit from the lightweight and corrosion-resistant properties of GRP, ensuring longevity while minimizing maintenance needs.

Conclusion

GRP dual lamination products represent a significant advancement in materials technology, combining the best attributes of glass fiber and plastic composites. Their durability, lightweight nature, customization potential, and resistance to environmental factors make them an invaluable choice for various applications across multiple industries. As technological advancements continue to evolve, the scope and potential of GRP dual lamination products will undoubtedly expand, solidifying their presence as a preferred material in the modern industrial arena.