-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

grp dual lamination products for enhanced durability and ...

Enhancing Durability with GRP Dual Lamination Products

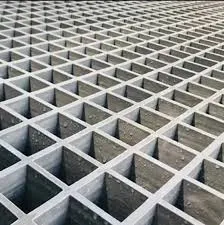

In today’s rapidly evolving industrial landscape, the demand for materials that not only meet performance expectations but also possess enhanced durability is higher than ever. One such innovation that has garnered attention is the use of Glass Reinforced Plastic (GRP) dual lamination products. These products, designed to withstand various environmental challenges, offer superior durability, making them ideal for a wide range of applications, from construction to transportation.

What is GRP Dual Lamination?

GRP, or Glass Reinforced Plastic, is a composite material made from a polymer matrix reinforced with fiberglass. The dual lamination process involves bonding two layers of GRP with an additional layer of reinforcement in between. This method results in a structure that exhibits remarkable strength, rigidity, and resistance to environmental degradation, such as moisture, temperature variations, and UV radiation.

The dual lamination not only enhances the mechanical properties of the material but also provides a barrier against potential corrosive elements. This aspect is particularly crucial in industries like marine, chemical, and wastewater management, where exposure to harsh conditions is common.

Durability and Performance Advantages

One of the standout features of GRP dual lamination products is their exceptional durability. Unlike traditional materials, which may suffer from wear and tear over time, GRP dual lamination products are designed to thrive in challenging environments. The combination of lightweight fiberglass and a sturdy polymer matrix ensures that the materials maintain their structural integrity under stress.

Furthermore, these products resist cracking, chipping, and other forms of damage that can arise due to environmental factors

. This durability translates into lower maintenance costs and extended product lifespan, making them a cost-effective solution for businesses looking to optimize their resources.Applications Across Various Industries

grp dual lamination products for enhanced durability and ...

The versatility of GRP dual lamination products allows them to be utilized across a broad spectrum of industries. In construction, for instance, they are used for cladding, roofing, and in the production of structural components. The excellent thermal insulation properties of GRP also contribute to energy efficiency in buildings.

In the marine industry, GRP products are favored for boat hulls and other components that must withstand continuous exposure to water and salt. The dual lamination process ensures that these products are not only lightweight but also robust enough to handle the rigors of marine environments without succumbing to corrosion.

In the chemical industry, GRP dual lamination is used for tanks, pipes, and other storage solutions that require resistance to a variety of corrosive substances. The reliability of these products ensures safe storage and transport, which is paramount in preventing leaks and spills that could pose environmental hazards.

Sustainability Considerations

As industries increasingly prioritize sustainability, the environmental impact of materials has come under scrutiny. GRP dual lamination products offer a sustainable alternative due to their longevity and reduced need for replacement. By decreasing the frequency of product turnover, businesses can significantly lower their resource consumption and waste generation.

Moreover, advancements in recycling technologies are beginning to make it possible to reclaim GRP materials for reuse. This aligns with the global movement towards circular economy practices, where the focus is on reusing and recycling materials to minimize environmental footprints.

Conclusion

In conclusion, GRP dual lamination products represent a significant advancement in the pursuit of durable and high-performance materials. Their ability to withstand harsh environmental conditions while providing structural integrity makes them an invaluable resource across various industries. With their cost-effectiveness, longevity, and potential for sustainability, GRP dual lamination products will undoubtedly play a pivotal role in shaping the future of materials engineering and industrial applications. As industries continue to innovate and evolve, the importance of durable solutions like GRP will only grow, paving the way for a more resilient and efficient future.