-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

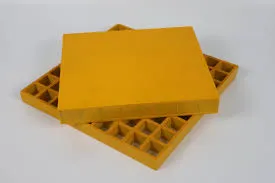

GRP Dual Lamination Solutions for Improved Durability and Longevity in Products

Enhancing Durability The Role of GRP Dual Lamination Products

In the ever-evolving landscape of materials science and engineering, the pursuit of enhanced durability and performance characteristics has led to the development of innovative solutions, especially in the field of composite materials. One such advancement is the utilization of Glass Reinforced Plastic (GRP) dual lamination products. These materials not only exhibit superior strength and longevity but also offer a range of applications across various industries, including construction, automotive, and aerospace.

Understanding GRP and Dual Lamination

Glass Reinforced Plastic, commonly referred to as fiberglass, is a composite material made from a polymer matrix reinforced with glass fibers. This combination results in a strong yet lightweight material that possesses excellent resistance to environmental factors such as corrosion, UV radiation, and chemical exposure. The dual lamination process enhances the inherent properties of GRP by applying multiple layers of control during the lamination process.

In dual lamination, two layers of the laminate are created, each optimized for specific performance traits. The first layer often focuses on structural integrity and strength, while the second layer can be tailored to enhance surface durability, resistance to wear, or aesthetic qualities. This method provides a synergistic effect that greatly improves the overall functionality of the composite material.

Applications of GRP Dual Lamination Products

GRP dual lamination products are increasingly employed in a multitude of sectors. In the construction industry, they are used for roofing, cladding, and structural components where weather resistance and longevity are critical. These materials can withstand harsh environmental conditions, reducing the need for frequent repairs and maintenance, ultimately leading to cost savings over time.

The automotive industry also benefits significantly from GRP dual lamination. Components such as body panels, structural elements, and interior fittings made from these materials are lighter and more durable than traditional metals or plastics. This weight reduction translates directly to improved fuel efficiency and performance of vehicles, which is increasingly crucial in today’s environmentally conscious market.

grp dual lamination products for enhanced durability and ...

In aerospace applications, the properties of GRP dual lamination enable the design of lightweight yet durable components, which are essential for enhancing fuel efficiency and overall performance

. The ability to withstand extreme operating conditions without degradation makes GRP an ideal choice for various aerospace applications, including fuselage components and wing structures.Advantages of GRP Dual Lamination

The advantages of GRP dual lamination products are manifold. Firstly, they offer exceptional resistance to moisture and chemical exposure, minimizing issues related to corrosion that often plague traditional materials. This durability extends the lifecycle of products, which is especially important in industries where equipment failure can lead to significant operational disruptions.

Secondly, dual lamination allows for customizable properties. Manufacturers can fine-tune the performance characteristics of each layer to meet specific demands, making it possible to create products that are not only strong but also tailored to the intended application. This versatility enhances the usability of GRP in specialized sectors where standard materials may fall short.

Moreover, the aesthetic appeal of GRP dual lamination products cannot be overlooked. The surface finish can be designed to meet various aesthetic requirements, providing an attractive solution that does not compromise on performance. This is particularly advantageous in applications where both functionality and appearance are critical.

Conclusion

GRP dual lamination products represent a significant advancement in materials technology, offering enhanced durability and versatility across a wide range of applications. The combination of glass fibers and polymer matrices, along with the benefits of dual lamination, provides engineers and manufacturers with a powerful tool to meet the ever-increasing demands for performance, longevity, and efficiency. As industries continue to seek innovative solutions to both environmental and operational challenges, the role of GRP dual lamination products is set to become even more prominent, paving the way for a new era of advanced composite materials.