-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

grp dual lamination products for enhanced durability and ...

Enhancing Durability with GRP Dual Lamination Products

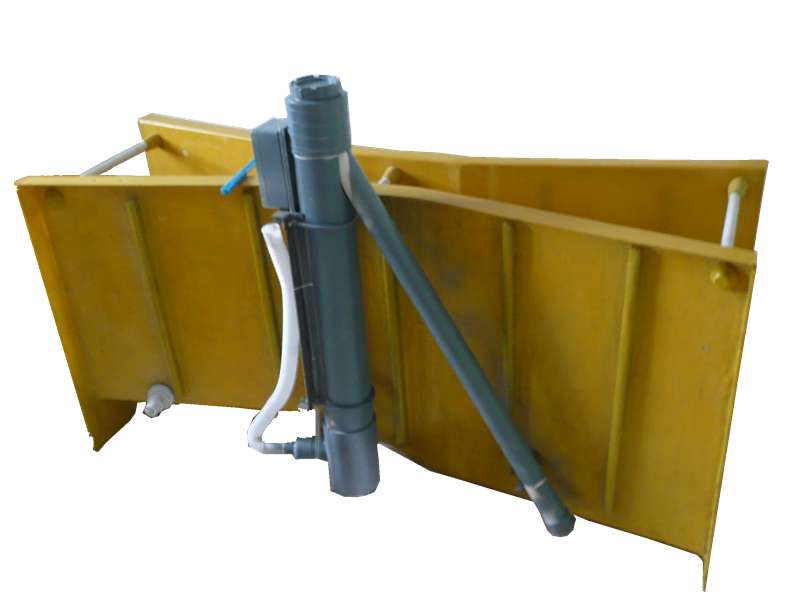

In an era where durability is paramount across various industries, the necessity for advanced materials cannot be overstated. Glass Reinforced Plastic (GRP), commonly known as fiberglass, has emerged as a significant player in this domain. Among its many applications, GRP dual lamination products offer enhanced durability, making them invaluable across sectors such as construction, automotive, marine, and even aerospace.

Understanding GRP and Dual Lamination

GRP is a composite material formed by combining glass fibers with a polymer matrix, creating a lightweight yet robust structure. Its strength-to-weight ratio is impressive, making it an ideal choice for applications that require resilience without adding excessive weight. The dual lamination process further enhances this composite by applying two layers of resin-infused fiberglass, leading to superior protection against environmental factors and mechanical stresses.

The dual lamination method involves applying one layer of fiberglass followed by an additional layer, resulting in a thicker, more durable finish. This technique not only fortifies the material but also provides a smooth surface that is easy to clean and maintain. The synergy between the strong glass fibers and the polymer matrix ensures that these products resist cracking, warping, and corrosion over time.

Applications of GRP Dual Lamination Products

1. Construction In the construction industry, GRP dual lamination products are increasingly used for facades, roofing, and structural components. Their lightweight nature facilitates easy handling, while their exceptional durability minimizes maintenance costs. Structures made from GRP can withstand harsh weather conditions, UV radiation, and even chemical exposure, making them suitable for a variety of climates.

2. Automotive The automotive sector has also embraced GRP dual lamination for components such as body panels and interior finishes. These parts benefit from the material’s ability to resist dents and scratches, essential for maintaining aesthetic appeal. Moreover, the lightweight nature of GRP contributes to enhanced fuel efficiency, aligning with the industry’s push towards sustainability and reduced emissions.

3. Marine Applications The marine industry relies heavily on materials that can endure exposure to saltwater and rough conditions. GRP dual lamination provides characteristics that are vital for boats and ships, such as resistance to corrosion and reduced weight for better fuel economy. Additionally, its insulation properties help in temperature control, making it a preferred choice for hulls and other marine structures.

4. Aerospace In aerospace applications, the quest for lightweight yet strong materials is never-ending. GRP dual lamination products are ideal for aircraft components, where every gram saved translates to efficiency. Their robustness helps reduce maintenance cycles and enhances the longevity of the aircraft, providing economic benefits to airlines.

grp dual lamination products for enhanced durability and ...

The Advantages of GRP Dual Lamination

The advantages of GRP dual lamination products extend beyond their applications. Here are some key benefits that define their rising popularity

- Enhanced Strength The combination of two laminated layers provides excellent tensile and compressive strength, making these products capable of withstanding significant stress over prolonged use.

- Corrosion Resistance GRP materials inherently resist corrosion, which is critical in environments subjected to moisture and chemicals. This resistance ensures a longer lifespan compared to traditional materials like metal and wood.

- Lightweight One of the most significant advantages of GRP dual lamination is its lightweight nature, which leads to easier transportation and installation.

- Low Maintenance The smooth surface and durability of these products result in lower long-term maintenance costs, making them a cost-effective solution for businesses.

- Versatile Design GRP can be molded into virtually any shape or design, providing aesthetic flexibility along with functional performance.

Conclusion

In a world that continuously demands greater durability from materials used in various applications, GRP dual lamination products stand out for their strength, lightweight nature, and resistance to environmental factors. As industries adopt more sustainable practices, these innovative materials offer solutions that encapsulate efficiency and longevity. As we move forward, the role of GRP dual lamination in enhancing product durability will not only benefit businesses but also contribute significantly to sustainability efforts across the globe.