-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 23, 2025 02:54

Back to list

grp dual lamination products for enhanced durability and ...

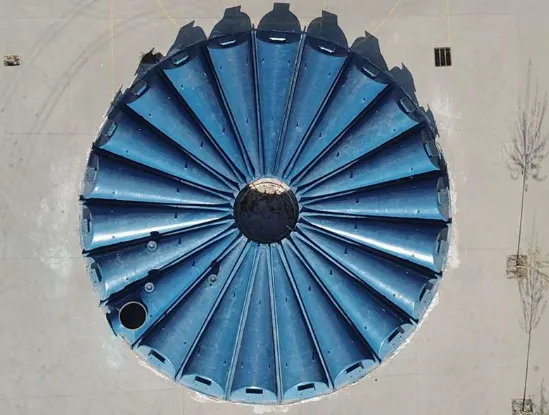

Glass Reinforced Plastic (GRP) dual lamination products represent a pivotal advancement in material engineering, offering unparalleled durability and resilience across various applications. As industries increasingly demand materials that promise longevity without compromising efficiency, GRP dual laminates emerge as a steadfast solution due to their distinctive composition and remarkable attributes.

From an authoritativeness perspective, the development and application of GRP dual laminates are backed by numerous certifications and endorsements from leading industrial bodies. These certifications are a testament to their superior performance characteristics and compliance with environmental and safety standards. Additionally, many industry experts and material scientists continuously advocate for the use of GRP dual laminates, underscoring their benefits in enhancing operational efficiency and sustainability. Trustworthiness in GRP dual laminate products is established through a proven track record of successful deployments in various industrial sectors. Testimonials and case studies from reputable companies demonstrate these products' ability to significantly reduce downtime, optimize maintenance cycles, and enhance overall operational reliability. Companies that have transitioned to GRP dual laminates often report significant improvements in productivity and a notable return on investment. In conclusion, GRP dual laminate products stand as a testament to the transformative power of advanced materials engineering. Their composite nature not only ensures enhanced durability but also positions them as an optimal choice for industries seeking sustainable and long-lasting solutions. Their proven performance, combined with expert backing and authoritative endorsements, establishes them as a trustworthy candidate for any application requiring robust and reliable material solutions. As industries evolve, embracing such innovations will undoubtedly pave the way for more efficient and resilient operations across multiple domains.

From an authoritativeness perspective, the development and application of GRP dual laminates are backed by numerous certifications and endorsements from leading industrial bodies. These certifications are a testament to their superior performance characteristics and compliance with environmental and safety standards. Additionally, many industry experts and material scientists continuously advocate for the use of GRP dual laminates, underscoring their benefits in enhancing operational efficiency and sustainability. Trustworthiness in GRP dual laminate products is established through a proven track record of successful deployments in various industrial sectors. Testimonials and case studies from reputable companies demonstrate these products' ability to significantly reduce downtime, optimize maintenance cycles, and enhance overall operational reliability. Companies that have transitioned to GRP dual laminates often report significant improvements in productivity and a notable return on investment. In conclusion, GRP dual laminate products stand as a testament to the transformative power of advanced materials engineering. Their composite nature not only ensures enhanced durability but also positions them as an optimal choice for industries seeking sustainable and long-lasting solutions. Their proven performance, combined with expert backing and authoritative endorsements, establishes them as a trustworthy candidate for any application requiring robust and reliable material solutions. As industries evolve, embracing such innovations will undoubtedly pave the way for more efficient and resilient operations across multiple domains.

Related Products