-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

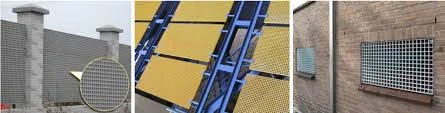

grp dual lamination products for enhanced durability and

Exploring GRP Dual Lamination Products for Enhanced Durability

In an era where durability and resilience in materials are of paramount importance, Glass Reinforced Plastic (GRP) Dual Lamination products have emerged as a revolutionary solution across various industries. With their advanced engineering and innovative design, these products offer enhanced durability, making them ideal for demanding environments. This article delves into the features, benefits, and applications of GRP Dual Lamination technology.

Understanding GRP Dual Lamination

GRP, commonly known as fiberglass, is widely recognized for its lightweight and strong properties. Dual lamination refers to the process of applying two layers of laminate, which effectively combines the strength of fiberglass with the enhanced performance characteristics of the resin layer. This method not only increases the mechanical strength of the product but also adds a layer of protection against environmental factors, including moisture, chemicals, and UV radiation.

Key Benefits of GRP Dual Lamination Products

1. Superior Strength and Durability The dual lamination process significantly improves the tensile and compressive strength of the materials. Products made from GRP dual lamination can withstand higher loads and resist deformation, making them suitable for structural applications in construction, transportation, and marine sectors.

2. Corrosion Resistance One of the most significant advantages of GRP dual lamination is its resistance to corrosion. Unlike traditional materials such as steel and wood, GRP does not rot or rust, ensuring a longer lifespan and reducing maintenance costs.

3. Lightweight Yet Robust GRP products are notably lighter than their metal or wooden counterparts, allowing for easier handling and installation. This property is particularly advantageous in industries where weight is a critical factor, such as aerospace and automotive manufacturing.

grp dual lamination products for enhanced durability and

4. Thermal and Electrical Insulation GRP is an excellent insulator, providing thermal and electrical resistance. This characteristic is beneficial in electrical applications, where machinery and equipment require protection from electrical failures and thermal damage.

5. Customizability GRP dual lamination products can be customized to meet specific requirements, including configurations, colors, and finishes. This flexibility is essential for industries that require tailored solutions for unique applications.

6. Environmental Impact With increasing emphasis on sustainability, GRP products are considered more environmentally friendly compared to traditional materials. Their longevity reduces the need for frequent replacements, thereby decreasing waste and resource consumption.

Applications of GRP Dual Lamination Products

The versatility of GRP dual lamination products allows them to find applications in numerous fields

- Construction Used for roofing systems, wall panels, and structural components due to their strength and weather resistance. - Transportation Ideal for lightweight and durable components in vehicles, trains, and boats to enhance fuel efficiency and performance. - Electrical and Telecommunications Utilized for enclosures and components that require excellent insulation and protection against environmental factors. - Chemical Processing Perfect for storage tanks, pipes, and fittings where corrosion resistance is essential.

Conclusion

As industries continuously seek materials that combine strength, durability, and cost-effectiveness, GRP dual lamination products stand out as an exceptional choice. Their capability to withstand harsh conditions while remaining lightweight and customizable makes them an invaluable asset in today’s market. As technology progresses, the potential for GRP dual lamination continues to expand, promising a future where innovative materials drive efficiency and sustainability across various sectors.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025