-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

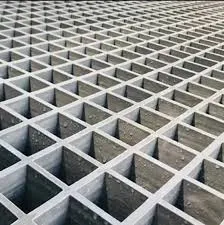

Optimizing GRP Duct System for Enhanced Efficiency and Performance Solutions

Understanding the GRP Duct System An Overview

In the domain of modern engineering, the quest for efficient and effective material solutions has led to the emergence of various innovative systems. One such system is the Glass Reinforced Plastic (GRP) duct system. This article aims to provide a comprehensive overview of GRP duct systems, their advantages, applications, and considerations in design and installation.

What is a GRP Duct System?

A GRP duct system consists primarily of ducts made from glass reinforced plastic, a composite material that combines high-strength fibers with a thermosetting resin. This combination results in a lightweight yet robust product, ideally suited for various industrial applications, particularly in HVAC (Heating, Ventilation, and Air Conditioning) systems. The structural integrity of GRP ensures that the ducts can withstand both physical and environmental stresses.

Advantages of GRP Duct Systems

The use of GRP duct systems offers several distinct advantages

1. Corrosion Resistance One of the most significant benefits of GRP is its resistance to corrosion. Unlike traditional materials, such as metal, GRP does not rust, making it particularly suitable for environments where exposure to moisture, chemicals, or saline conditions is common.

2. Lightweight The lightweight nature of GRP facilitates easier handling and installation. This characteristic can lead to reduced labor costs and time when compared to heavier materials like steel or concrete.

3. Thermal Insulation GRP ducts offer excellent thermal insulation properties, which can enhance energy efficiency in HVAC applications. This means reduced thermal losses and minimized energy consumption for heating and cooling.

4. Low Maintenance With its inherent properties, GRP requires minimal maintenance over its lifespan. This translates to lower operational costs and less downtime for repairs.

5. Design Flexibility The manufacturing process of GRP allows for various shapes and sizes, providing flexibility in design configurations. This can be advantageous in complex building designs where space and aesthetics are critical.

Applications of GRP Duct Systems

grp duct system

GRP duct systems find applicability across multiple sectors. Common applications include

- HVAC Systems In commercial and industrial buildings, GRP ducts are fundamental for efficient air distribution. - Chemical Processing Due to their corrosion resistance, GRP ducts are ideal for conveying gases or fumes in chemical plants.

- Marine Applications The maritime industry benefits from GRP ducts for ventilation and exhaust systems, given the need for durability against salty environments.

- Wastewater Management GRP is often used in sewage and stormwater systems due to its resistance to chemicals typically found in wastewater.

Design and Installation Considerations

When designing and installing a GRP duct system, several factors must be taken into account

1. Load Bearing While GRP is lightweight, designers must evaluate the loads that ducts may encounter, including external pressures and internal airflow dynamics.

2. Joint Design Proper sealing and joint design are critical to prevent leaks. It is essential to select compatible jointing methods that ensure durability and ease of maintenance.

3. Environmental Factors Consider the environmental conditions, such as temperature variations and exposure to chemicals, to select the appropriate resin and glass fibers.

4. Regulatory Compliance Ensure that the GRP duct system adheres to local building codes and environmental regulations, particularly for applications in sensitive areas.

Conclusion

The GRP duct system represents a significant advancement in ducting solutions, offering a myriad of benefits that cater to the demands of modern engineering projects. With their unique properties and versatility, GRP ducts are well-suited for a variety of applications, from HVAC systems to chemical processing facilities. Understanding the advantages, applications, and key considerations associated with GRP ducts can empower engineers and architects to make informed decisions, ultimately leading to enhanced operational efficiency and longevity in their projects.