-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

grp fan

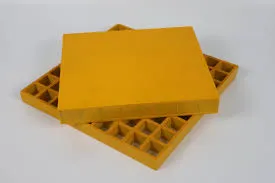

The Evolution and Impact of GRP (Glass Reinforced Plastic) in Various Industries

In recent years, materials innovation has played a crucial role in the evolution of various industries. One of the most remarkable advancements is the use of Glass Reinforced Plastic (GRP), often referred to as fiberglass. This versatile composite material, which combines plastic with glass fibers, has revolutionized sectors ranging from construction to automotive and marine design.

Understanding GRP Composition and Properties

GRP is composed of a polymer matrix reinforced with glass fibers, which significantly enhance its strength, durability, and resistance to environmental factors. The polymer base provides flexibility and ease of molding, while the glass fiber reinforces the composite, making it lighter and stronger than traditional materials like steel or wood. The resulting product is a lightweight, corrosion-resistant, and highly durable material that can withstand harsh conditions, making it ideal for a variety of applications.

One of GRP's standout features is its excellent strength-to-weight ratio. This property allows manufacturers to produce components that are both lightweight and strong, leading to efficiencies in transportation and construction. Additionally, GRP can be molded into complex shapes, enabling innovative designs that were previously difficult to achieve with conventional materials.

Applications of GRP in Various Industries

1. Construction

In the construction industry, GRP has gained popularity for its application in structural components, roofing systems, and wall panels. Its resistance to moisture and chemicals makes it an excellent choice for environments susceptible to corrosion. Moreover, GRP can be used in lightweight structures, which reduces the load on foundations and supports, potentially lowering building costs. The design flexibility also allows for aesthetic finishes that can enhance visual appeal without compromising durability.

2. Marine Industry

The marine sector was one of the first to embrace GRP due to its lightweight and corrosion-resistant characteristics. Fiberglass boats, for instance, offer superior performance compared to their wooden and metal counterparts. They are less susceptible to rot and can better withstand the effects of saltwater. GRP is also used in the construction of marine components such as hulls, decks, and storage facilities, contributing to the longevity and efficiency of vessels.

grp fan

3. Automotive Engineering

The automotive industry has seen a significant adoption of GRP for manufacturing vehicle components, such as body panels, bumpers, and interior parts. The lightweight nature of GRP contributes to better fuel efficiency and reduced emissions. Additionally, it allows for more creative and aerodynamic vehicle designs. As electric vehicles become more prevalent, the demand for lightweight materials like GRP is expected to increase, aiding in the drive towards sustainability.

4

. Energy SectorThe renewable energy sector, particularly in wind turbine manufacturing, increasingly utilizes GRP for constructing turbine blades. The material’s lightweight properties help improve energy efficiency while minimizing the structural requirements. Wind turbine blades made of GRP are not only stronger and lighter but also offer greater resistance to the environmental challenges of wind farming.

Environmental Considerations and Future Trends

Despite its many advantages, GRP does have environmental implications. The production of fiberglass involves energy-intensive processes, and disposal poses challenges due to its durability, which can prevent decomposition. However, advancements in recycling technologies and the development of bio-based resins are paving the way for more sustainable practices in the GRP industry.

Looking forward, the future of GRP appears promising. Research is ongoing to improve its properties and applications, such as incorporating smart technologies into GRP composites. Innovations like self-healing materials and integration with sensors could further enhance GRP's functionality in various applications.

Conclusion

The rise of Glass Reinforced Plastic has marked a significant turning point across multiple industries. Its unique combination of strength, lightweight properties, and versatility makes it a preferred choice for modern manufacturing. As industries continue to innovate and seek sustainable solutions, GRP is likely to remain at the forefront of material science, driving advancements that shape our built environment and technologies for years to come.