-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding GRP Flanges and Their Applications in Modern Engineering

Understanding GRP Flanges A Comprehensive Overview

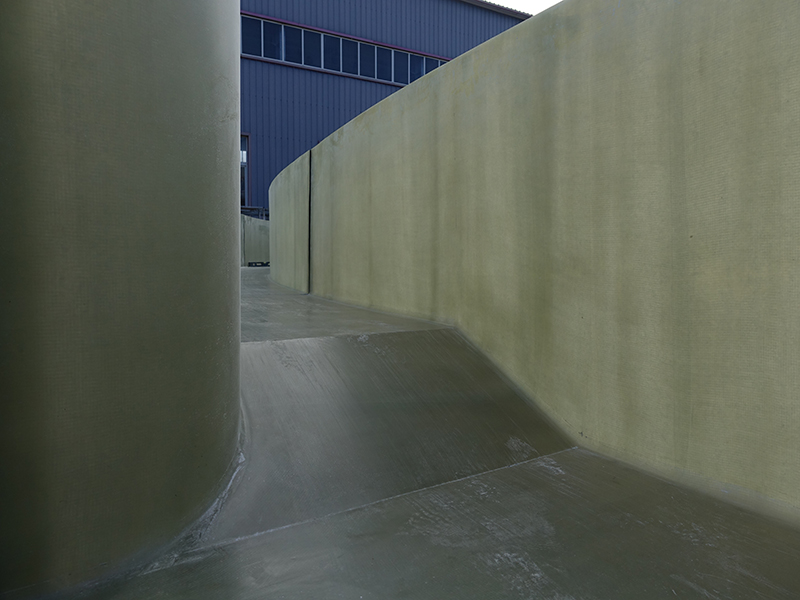

Glass Reinforced Plastic (GRP) flanges are a pivotal component in modern engineering and construction, widely recognized for their superior strength, durability, and corrosion resistance. These flanges play a crucial role in various piping systems, particularly in industries such as water treatment, chemical processing, oil and gas, and marine applications. In this article, we will delve into what GRP flanges are, their benefits, applications, and installation considerations, providing a thorough understanding of this essential engineering component.

What is a GRP Flange?

A GRP flange is a type of flange made from glass reinforced plastic, a composite material that combines a polymer matrix – typically a thermosetting resin – with glass fibers. This combination results in a material that is both lightweight and incredibly strong, making it an excellent choice for applications that require robust performance in harsh environments. The manufacturing process involves molding the material into various shapes, including standard sizes that can easily interface with existing piping systems.

Advantages of GRP Flanges

1. Corrosion Resistance One of the standout features of GRP flanges is their exceptional resistance to corrosion. Unlike traditional metal flanges, which can rust and degrade over time, GRP flanges maintain their integrity when exposed to harsh chemicals and salty environments. This makes them particularly suited for applications in waste management and marine environments.

2. Lightweight The lightweight nature of GRP flanges allows for easier handling and installation. This is especially advantageous in large-scale projects where heavy components can complicate logistics and increase installation costs.

3. Low Thermal Conductivity GRP materials have low thermal conductivity, which helps in reducing energy loss and maintains temperature stability within the piping systems. This property is vital in applications requiring thermally sensitive materials.

4. Cost-Effective While the initial cost of GRP flanges may be higher than traditional materials, their longevity and maintenance-free characteristics often make them more cost-effective in the long run. Reduced maintenance needs and extended lifespans can lead to significant savings.

5. Versatile Applications GRP flanges can be manufactured in a variety of shapes and sizes, making them adaptable to different systems. Their ability to conform to various designs makes them highly versatile in numerous industries.

Applications of GRP Flanges

grp flange

GRP flanges are found in a wide range of applications, including

- Water and Wastewater Treatment Their resistance to corrosion and chemical degradation makes GRP flanges ideal for transporting water and wastewater in treatment plants.

- Chemical Industry In environments where aggressive chemicals are handled, GRP flanges can withstand exposure without significant degradation.

- Oil and Gas The lightweight nature and resistance to corrosion make GRP flanges suitable for offshore and onshore oil operations.

- Marine Due to their excellent resistance to saltwater and marine growth, GRP flanges are often used in boat and dock applications.

- HVAC Systems In heating, ventilation, and air conditioning systems, GRP flanges can help ensure a lightweight and efficient solution for joining ductwork.

Installation Considerations

When installing GRP flanges, it’s crucial to follow specific guidelines to ensure a successful and trouble-free installation. Proper alignment during installation is essential to avoid undue stress on the flanges and the piping system. The use of appropriate gaskets is also important to provide a watertight seal, preventing leaks.

Furthermore, technicians should be trained in handling GRP materials, as they require different tools and methods compared to metal flanges. Maintaining a clean surface before fitting the flanges is essential, as contaminants can lead to compromised seals.

Conclusion

GRP flanges represent an innovative solution in piping systems, offering numerous advantages over traditional materials. Their resistance to corrosion, lightweight and versatile nature, and cost-effectiveness make them an appealing choice for a variety of applications. As industries continue to evolve and demand more efficient and durable solutions, GRP flanges are poised to play an increasingly vital role in modern infrastructure. Understanding the properties and best practices associated with these flanges can lead to improved project outcomes and operational efficiency.