-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

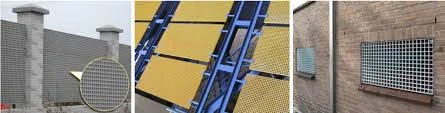

grp flange

Understanding GRP Flanges A Comprehensive Overview

Glass Reinforced Plastic (GRP) flanges are an integral part of various engineering applications, particularly in industries such as construction, water treatment, chemical processing, and power generation. Their lightweight yet robust characteristics make them an attractive alternative to traditional metallic flanges. In this article, we will explore the composition, advantages, applications, and maintenance of GRP flanges, providing a holistic view of their significance within modern engineering practices.

Composition of GRP Flanges

GRP flanges are composed of a polyester or epoxy resin reinforced with glass fibers. This composite material combines the strengths of both glass fibers and resins, resulting in a sturdy structure capable of withstanding high pressures and loads. The production process often involves molding techniques such as hand lay-up, vacuum infusion, or resin transfer molding, ensuring that the final product meets specific performance and durability standards.

The choice of resin significantly influences the performance and application of GRP flanges. Polyester resins are commonly used for general-purpose applications, but for more demanding environments involving chemical exposure or extreme temperatures, epoxy resins may be preferred due to their superior strength and chemical resistance. Additionally, additives can be incorporated into the materials to enhance properties such as UV resistance or flame retardation.

Advantages of GRP Flanges

1. Corrosion Resistance One of the most significant advantages of GRP flanges is their resistance to corrosion. Unlike metal flanges, which can rust and degrade when exposed to moisture and various chemicals, GRP flanges remain intact and maintain their structural integrity over time. This property makes them particularly valuable in industries dealing with corrosive substances, such as wastewater treatment or chemical manufacturing.

2. Lightweight GRP flanges are significantly lighter than their metal counterparts, making them easier to transport and install. This reduction in weight can lead to lower transportation costs and simpler handling during installation, ultimately resulting in cost savings in large-scale projects.

grp flange

3. Thermal Insulation GRP materials possess excellent thermal insulation properties, which help in maintaining temperature stability within pipelines and reducing energy costs in temperature-sensitive applications.

4. Cost-Effectiveness Although the initial cost of GRP flanges may be higher than that of standard metal flanges, their durability and low maintenance requirements can lead to substantial long-term savings. The reduction in replacement and repair frequency offsets the initial investment.

Applications of GRP Flanges

GRP flanges are utilized in a variety of applications, thanks to their unique properties. Common uses include

- Water and Wastewater Infrastructure In treatment plants and effluent systems, GRP flanges provide reliable sealing and connections without the risk of corrosion. - Chemical Processing The resistance to aggressive chemicals makes GRP flanges an ideal choice for chemical plants. - Oil and Gas With the need for lightweight components that can withstand harsh environments, GRP flanges are becoming increasingly popular in pipeline systems. - Power Generation In wind turbine installations and geothermal plants, the low weight and excellent performance make GRP flanges advantageous.

Maintenance Considerations

While GRP flanges are low-maintenance, regular inspections are essential to ensure their longevity. Visual inspections can help identify any surface damage or wear, and appropriate cleaning methods should be employed to avoid the buildup of debris that might affect performance.

In conclusion, GRP flanges present a versatile, cost-effective solution for various sectors. Their combination of lightweight, corrosion resistance, and thermal insulation properties makes them superior alternatives to traditional materials. As industries continue to seek durable and efficient components, GRP flanges will undoubtedly play an increasingly prominent role in engineering solutions for the 21st century.