-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

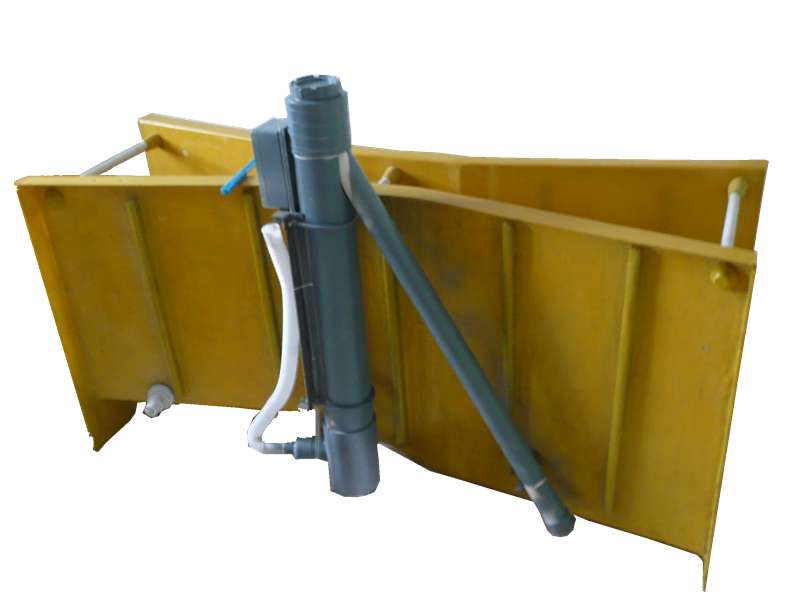

grp food grade equipment

Understanding GRP Food Grade Equipment A Key to Quality and Safety in the Food Industry

In the food processing industry, equipment quality and safety are paramount. One of the primary materials that has gained prominence in this sector is Glass Reinforced Plastic (GRP). GRP food grade equipment is increasingly becoming the preferred choice for manufacturers and operators alike due to its numerous beneficial properties, which enhance both food safety and operational efficiency.

Understanding GRP Food Grade Equipment A Key to Quality and Safety in the Food Industry

Another significant advantage of GRP food grade equipment is its ease of cleaning and maintenance. Hygiene is critical in food production, as it prevents microbial growth and contamination. GRP surfaces can be designed to be smooth and non-porous, minimizing the risk of bacteria accumulating in hard-to-clean areas. Furthermore, GRP can withstand high temperatures and various cleaning chemicals, allowing for effective sanitation processes without damaging the equipment.

grp food grade equipment

Durability is another essential characteristic of GRP food grade equipment. Unlike metal, which can rust, or wood, which can warp, GRP maintains its structural integrity over time. This durability translates into lower maintenance costs and extended lifespan, making it a cost-effective solution for food manufacturers. Investing in GRP equipment can lead to significant savings in both maintenance and replacement costs in the long run.

Additionally, the versatility of GRP allows for its application in various forms and shapes, catering to specific operational needs. From storage tanks to conveyor belts and food processing machinery, GRP can be molded into complex designs that fulfill specific requirements. This customization not only improves efficiency but also ensures that businesses can tailor their equipment to meet the evolving demands of the food industry.

Furthermore, the lightweight nature of GRP equipment simplifies installation and relocation. This feature is particularly beneficial for food processing plants that may need to adapt their layouts or expand operations. The reduced weight also means that transport costs are lower, an attractive factor for many businesses looking to optimize their supply chain.

In summary, GRP food grade equipment represents a significant advancement in the food processing industry, offering unmatched advantages in terms of durability, hygiene, and adaptability. As food safety regulations become increasingly stringent, the demand for high-quality food-grade materials will continue to grow. By investing in GRP equipment, food manufacturers can ensure their operations not only meet regulatory standards but also contribute to the overall safety and quality of the food supply. Embracing this innovative material could very well be the key to future-proofing food processing facilities and maintaining competitive advantages in an ever-evolving market.