-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

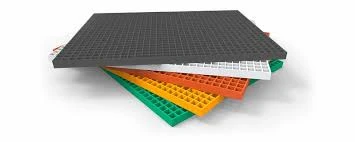

grp food grade equipment

Understanding GRP Food Grade Equipment Essential for Safe Food Processing

In the food processing industry, ensuring the safety and quality of products is paramount. This is where GRP (Glass Reinforced Plastic) food grade equipment comes into play. GRP is extensively used in various sectors due to its unique properties, making it an ideal choice for food processing applications. In this article, we will explore the benefits, applications, and the importance of GRP food grade equipment in maintaining food safety standards.

What is GRP Food Grade Equipment?

GRP food grade equipment is specifically designed to be safe for food contact. Composed of a polymer matrix reinforced by glass fibers, GRP offers a combination of lightweight, durability, and resistance to corrosion. This makes it particularly suitable for environments where hygiene and cleanliness are critical. The food grade aspect refers to the materials used in the equipment, ensuring they meet stringent regulatory standards for safety when in contact with food products.

Benefits of GRP Food Grade Equipment

1. Hygiene and Safety One of the primary advantages of GRP equipment is its non-porous surface, which helps prevent the buildup of bacteria and contaminants. This characteristic is crucial in food processing, where hygiene is vital to avoid foodborne illnesses.

2. Durability and Longevity GRP is known for its strength and resistance to various chemicals, including acidic and alkaline substances often found in food processing environments. This durability translates to a longer lifespan for equipment, reducing the need for frequent replacements and maintenance.

3. Lightweight Compared to traditional materials like metal or concrete, GRP is significantly lighter. This makes installation and handling easier, which can contribute to operational efficiencies in food processing facilities.

grp food grade equipment

4. Customizable GRP can be molded into various shapes and sizes, allowing manufacturers to create customized solutions tailored to specific food processing needs. This flexibility helps businesses optimize their production lines without compromising safety.

5. Corrosion Resistance Since GRP is resistant to corrosion, it can withstand harsh cleaning chemicals and environmental conditions without degrading. This characteristic is vital in maintaining the integrity of food processing equipment.

Applications of GRP Food Grade Equipment

GRP food grade equipment is widely used in various applications within the food industry. Some common examples include

- Storage Tanks GRP tanks are ideal for storing liquids, such as oils, sauces, and other food products, while ensuring contamination-free conditions. - Conveyor Systems Food grade GRP components can be integrated into conveyor systems, facilitating the safe movement of food products through different stages of processing. - Piping Systems GRP pipes are used for transporting liquids and slurries, providing a safe and durable solution for food processing facilities. - Workstations and Machinery Custom GRP workstations, tables, and machinery parts ensure that food handling meets safety regulations while offering ease of cleaning.

Conclusion

The importance of GRP food grade equipment cannot be overstated in today’s food processing industry. With the growing emphasis on food safety and quality, adopting materials that meet regulatory standards while providing efficiency and durability is essential. GRP food grade equipment not only helps businesses comply with industry regulations but also enhances overall operational performance. By investing in high-quality GRP solutions, food processors can ensure the safety and quality of their products, ultimately contributing to consumer trust and satisfaction.