-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Properties and Applications of Grating Structures in Optical Systems

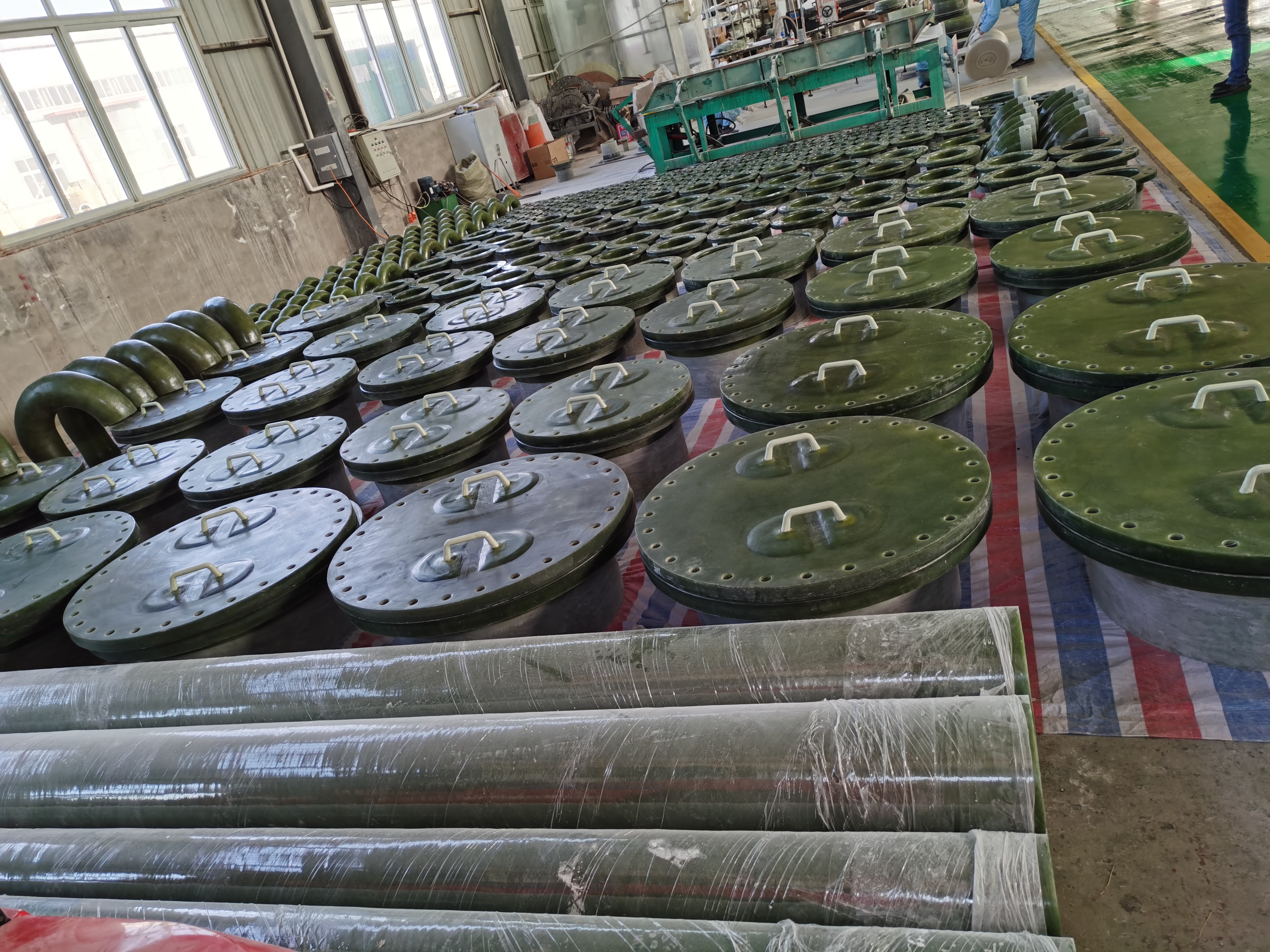

Understanding GRP Grating Applications and Benefits

Glass Reinforced Plastic (GRP) grating, often referred to as fiberglass grating, has emerged as a versatile material with a wide range of applications across various industries. This innovative product is made from a composite material consisting of fiberglass and resin, offering exceptional strength, durability, and resistance to various environmental factors. In this article, we will explore the features, advantages, and uses of GRP grating, highlighting why it has become a popular choice in many sectors.

What is GRP Grating?

GRP grating is a type of industrial flooring solution that is composed of tightly wound fiberglass strands embedded in a resin matrix. This combination not only enhances the structural integrity of the grating but also makes it lightweight compared to traditional materials such as steel or aluminum. Furthermore, GRP grating can be manufactured in a variety of sizes and thicknesses, making it adaptable for different applications, whether in industrial settings, commercial spaces, or even residential environments.

Key Features of GRP Grating

1. Corrosion Resistance One of the primary advantages of GRP grating is its high resistance to corrosion. Unlike metal grates, which can rust and deteriorate when exposed to chemicals or the elements, GRP maintains its integrity over time, even in harsh environments such as wastewater treatment plants or chemical processing facilities.

2. Non-slip Surface GRP grating can be designed with a non-slip surface, enhancing safety in environments where wet or slippery conditions may exist. This feature is particularly valuable in industries like food processing, marine applications, and outdoor walkways.

3. Lightweight The lightweight nature of GRP grating allows for easier handling and installation. This reduces labor costs and the need for heavy machinery during installation, making it a cost-effective solution.

4. Versatility GRP grating is available in a range of colors and designs, allowing it to be used not just for functional purposes but also for aesthetic ones. It can be utilized in various settings, from industrial floors to decorative walkways in parks.

grp grating

5. UV Resistance This material is engineered to withstand UV exposure, preventing degradation over time. This characteristic makes GRP grating an ideal choice for outdoor applications where sunlight can be an issue.

Applications of GRP Grating

GRP grating has found its place in multiple sectors, including

- Industrial Applications In factories and warehouses, GRP grating is commonly used for walkways, platforms, and staircases. Its strength and chemical resistance make it suitable for environments that involve the handling of aggressive substances.

- Infrastructure GRP grating is increasingly used in infrastructure projects, such as bridges and drainage systems, owing to its lightweight nature and resistance to corrosion, which prolongs the lifespan of the structures.

- Marine Industry The marine environment is particularly harsh on materials, making GRP grating an excellent choice for docks, piers, and boat ramps, as it can withstand exposure to saltwater and other damaging factors.

- Environmental Applications Wastewater treatment facilities often utilize GRP grating for walkways and platforms, as it is resistant to chemicals and moisture, enhancing the safety of workers in such environments.

Conclusion

The numerous attributes of GRP grating—corrosion resistance, non-slip surface, lightweight, and versatility—make it a compelling choice for a wide array of applications across different industries. As industries continue to seek innovative materials that enhance safety, performance, and longevity, GRP grating stands out as a prime candidate. Its growing popularity attests to its effectiveness and the pivotal role it plays in modern industrial solutions. Whether used in a factory, a pier, or a decorative walkway, GRP grating offers benefits that are hard to overlook.