-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

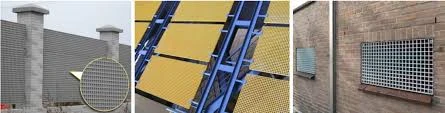

grp grating

Understanding GRP Grating An Essential Material for Modern Applications

Glass Reinforced Plastic (GRP) grating, also known as fiberglass grating, is a versatile and innovative material that has gained prominence across various industries. Its combination of strength, durability, and lightweight properties makes it an ideal choice for multiple applications, from industrial flooring to architectural elements. In this article, we will explore the characteristics, benefits, and applications of GRP grating, highlighting why it has become a go-to material for many engineering and construction projects.

What is GRP Grating?

GRP grating is manufactured by combining glass fibers with a resin matrix, usually polyester or vinyl ester. This process creates a composite material that offers exceptional strength-to-weight ratios. GRP grating comes in various shapes and sizes, including standard panels, custom configurations, and different mesh patterns, which cater to specific load-bearing and aesthetic requirements.

Key Benefits of GRP Grating

1. Corrosion Resistance One of the standout features of GRP grating is its resistance to corrosion. Unlike traditional materials like steel or aluminum, GRP is not susceptible to rust or degradation when exposed to harsh chemicals, water, or extreme weather conditions. This property is particularly beneficial for marine, chemical processing, and wastewater treatment applications.

2. Lightweight and Easy to Handle GRP grating is significantly lighter than steel or concrete alternatives. This lightweight characteristic makes it easier to transport, install, and maneuver during construction. It reduces the overall weight of structures, thus lowering transportation costs and ensuring easier maintenance.

3. Safety Safety is paramount in industrial and commercial settings. GRP grating provides enhanced slip resistance due to its surface texture and can be manufactured with anti-slip additives. This feature ensures personnel safety, especially in environments prone to spills or wet conditions.

4. Low Maintenance Once installed, GRP grating requires minimal maintenance. Its resistance to corrosion and the elements means that it doesn’t need frequent painting or treatment, thus reducing long-term maintenance costs for facilities.

5. Aesthetic Versatility GRP grating can be produced in various colors and finishes, making it suitable for aesthetic applications in architectural designs. It can blend seamlessly with modern building designs while maintaining functionality.

grp grating

Applications of GRP Grating

The versatility of GRP grating enables its use in numerous sectors. Here are some primary applications

- Industrial Flooring GRP grating is commonly used in chemical plants, refineries, and manufacturing facilities due to its load-bearing capacity and resistance to corrosive substances. It allows for the safe passage of personnel and equipment.

- Walkways and Platforms Its lightweight nature makes GRP grating an excellent choice for constructing walkways, platforms, and staircases, particularly in environments where traditional materials may pose an operational challenge.

- Marine Applications Given its resistance to saltwater and chemicals, GRP grating is widely utilized in docks, marinas, and aboard ships. It contributes to safer walking surfaces while minimizing maintenance concerns.

- Water Treatment Facilities In wastewater treatment plants, where exposure to corrosive substances is a concern, GRP grating is favored for catwalks, platforms, and ancillary structures.

- Architectural Features Beyond industrial settings, GRP grating is also used in various architectural features, such as canopies, skylights, and decorative elements, providing strength while enhancing the visual appeal of buildings.

Conclusion

In conclusion, GRP grating is a remarkable material that offers various advantages in construction and industrial applications. Its resistance to corrosion, lightweight nature, safety features, and low maintenance requirements make it an ideal choice for modern needs. As industries continue to evolve and prioritize safety and efficiency, the role of GRP grating is likely to expand, making it an essential component in future projects. Whether in industrial or architectural contexts, GRP grating represents a blend of functionality and innovation that is hard to overlook.