-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

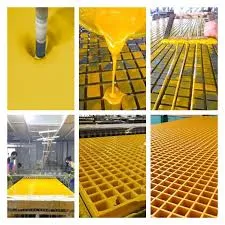

Exploring the Characteristics and Applications of GRP Grating Systems in Industrial Settings

Understanding GRP Grating A Comprehensive Overview

GRP (Glass Reinforced Polymer) grating has emerged as a superior alternative to traditional materials in various industrial applications. This innovative product is made by embedding glass fibers within a polymer matrix, resulting in a lightweight yet extremely strong material. Its unique properties make GRP grating an increasingly popular choice across industries, including construction, wastewater treatment, and chemical processing.

Composition and Manufacturing Process

GRP grating is composed of a combination of resins and glass fibers, which are processed into a grid-like structure. The manufacturing process typically involves pultrusion, where continuous strands of glass are pulled through a resin bath and then cured to form a solid structure. This results in a product that is not only durable but also resistant to corrosion, UV light, and harsh chemicals. The incorporation of glass fibers enhances the tensile strength, ensuring that GRP grating can withstand heavy loads and resist deformation over long periods.

Key Advantages

One of the primary benefits of GRP grating is its lightweight nature. Compared to steel or aluminum grating, GRP is significantly lighter, making it easier to transport and install. This feature can lead to reduced labor costs and faster installation times. Additionally, GRP grating is non-conductive, making it an excellent choice for environments where electrical hazards are a concern.

Another critical advantage is the material's resistance to corrosion. Traditional grating materials like steel can rust over time, especially in environments exposed to water and chemicals. In contrast, GRP grating maintains its integrity in corrosive environments, extending its lifespan and reducing maintenance costs. This durability makes it particularly suitable for use in sewage treatment plants, chemical plants, and offshore applications.

Moreover, GRP grating is designed to be slip-resistant, providing a safe walking surface in wet or oily conditions. This is achieved through the addition of textured surfaces, which enhance grip and reduce the risk of accidents. The safety aspect is crucial, particularly in industrial settings where poor footing can lead to serious injuries.

grp grating

Applications of GRP Grating

The versatility of GRP grating allows it to be used in various applications. In the construction industry, it is commonly utilized for walkways, platforms, and stair treads. Its lightweight and strong nature simplifies the design and construction process, allowing for more efficient project completion.

In the wastewater treatment industry, GRP grating is favored for its resistance to corrosive substances. It is often used in clarifiers, aeration tanks, and sludge handling systems. The material's low maintenance requirements also make it an economical choice over the long term.

Furthermore, GRP grating is widely employed in the chemical processing sector. It can safely support personnel and equipment in areas where exposure to harsh chemicals is inevitable. The non-conductive properties of GRP grating provide additional safety in environments where electrical hazards exist, such as in power plants or manufacturing facilities.

Environmental Considerations

In addition to its practical advantages, GRP grating also presents environmental benefits. The extended lifespan of the material reduces the need for replacements, leading to less waste. Moreover, many manufacturers are now focusing on creating sustainable products, using recyclable materials in their production processes. By opting for GRP grating, industries can minimize their environmental footprint while still achieving high-performance outcomes.

Conclusion

In summary, GRP grating offers an unparalleled combination of strength, durability, and safety, making it a preferred choice across numerous industries. Its lightweight and corrosion-resistant properties, along with its versatile applications, underline its growing popularity in modern engineering solutions. As industries continue to prioritize safety and sustainability, GRP grating stands out as a smart investment for the future, ensuring both performance and responsibility in industrial settings. As we move forward, understanding and incorporating materials like GRP grating will be essential in creating safer and more efficient working environments.