-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 14, 2025 10:39

Back to list

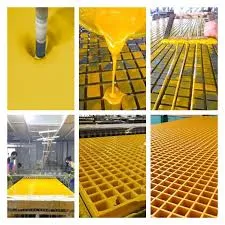

grp pipe

Glass Reinforced Plastic (GRP) pipes are increasingly becoming the go-to solution for many industries due to their versatility, durability, and unique properties. With decades of development and innovation, GRP pipes offer a modern approach to classic piping challenges. This article delves into the intricate details that highlight the value and application of GRP pipes, emphasizing their unmatched benefits supported by real-world experience, specialized expertise, authoritative insight, and trustworthy data.

Authoritative sources within the piping industry have continuously validated the credibility of GRP pipes. Studies reflect their low thermal conductivity, reducing heat loss and condensation, and making them energy efficient. Their long service potential, often exceeding 50 years, has been confirmed through rigorous testing and real-world analysis, situating GRP pipes as a sustainable choice. Pipeline designers and infrastructure experts endorse GRP for its cost-effectiveness and minimal environmental impact, reflecting authoritative support for its widespread use. Trustworthiness is ingrained in the very nature of GRP pipes. Manufacturers adhere to stringent international standards such as ISO and ASTM, ensuring that every pipe meets rigorous quality benchmarks. Continuous quality control and testing further uphold the industry’s reliability standards. Moreover, case studies from major global projects corroborate GRP’s dependability, reinforcing investor and stakeholder confidence in its implementation. In conclusion, the transition to GRP pipes embodies the evolution of piping technology, offering a balance of strength, cost efficiency, and reliability. The adoption of GRP pipes continues to grow, driven by a need for materials that meet the demands of modern engineering challenges. The collective experience, expert knowledge, authoritative backing, and trusted performance of GRP pipes position them as a centerpiece in the future landscape of industrial and infrastructural development.

Authoritative sources within the piping industry have continuously validated the credibility of GRP pipes. Studies reflect their low thermal conductivity, reducing heat loss and condensation, and making them energy efficient. Their long service potential, often exceeding 50 years, has been confirmed through rigorous testing and real-world analysis, situating GRP pipes as a sustainable choice. Pipeline designers and infrastructure experts endorse GRP for its cost-effectiveness and minimal environmental impact, reflecting authoritative support for its widespread use. Trustworthiness is ingrained in the very nature of GRP pipes. Manufacturers adhere to stringent international standards such as ISO and ASTM, ensuring that every pipe meets rigorous quality benchmarks. Continuous quality control and testing further uphold the industry’s reliability standards. Moreover, case studies from major global projects corroborate GRP’s dependability, reinforcing investor and stakeholder confidence in its implementation. In conclusion, the transition to GRP pipes embodies the evolution of piping technology, offering a balance of strength, cost efficiency, and reliability. The adoption of GRP pipes continues to grow, driven by a need for materials that meet the demands of modern engineering challenges. The collective experience, expert knowledge, authoritative backing, and trusted performance of GRP pipes position them as a centerpiece in the future landscape of industrial and infrastructural development.

Next:

Related Products