-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

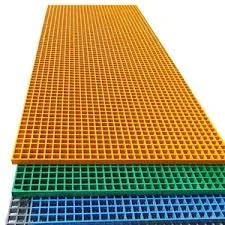

grp pipes and fittings for ship building

GRP Pipes and Fittings for Shipbuilding A Comprehensive Overview

In the maritime industry, the choice of materials for constructing ships is crucial for ensuring durability, safety, and efficiency. One of the materials that has gained significant traction in recent years is Glass Reinforced Plastic (GRP). GRP pipes and fittings are increasingly being utilized in shipbuilding projects due to their unique properties and advantages over traditional materials like steel and iron. This article will explore the benefits of GRP pipes and fittings in shipbuilding, their applications, and the factors driving their adoption.

Advantages of GRP Pipes and Fittings

1. Corrosion Resistance One of the most significant benefits of GRP is its exceptional resistance to corrosion. Ships are exposed to harsh marine environments, where saltwater can cause rapid degradation of conventional materials. GRP, on the other hand, is inherently resistant to corrosion, making it an ideal choice for piping systems that are in direct contact with seawater.

2. Lightweight GRP is considerably lighter than traditional materials such as steel and cast iron. This weight reduction translates into lower fuel consumption for vessels, as lighter ships require less energy to move through water. Additionally, the lighter weight allows for increased cargo capacity, making GRP an economically advantageous choice for shipbuilders.

3. Durability and Longevity GRP pipes and fittings offer remarkable durability and can withstand high levels of stress and impact without compromising structural integrity. The lifespan of GRP materials can exceed that of traditional alternatives, reducing the need for frequent replacements and repairs, thereby lowering overall maintenance costs.

4. Flexibility in Design The manufacturing process of GRP allows for greater design flexibility compared to traditional materials. Shipbuilders can create complex shapes and sizes with relative ease, enabling the development of custom solutions that meet specific operational requirements. This flexibility can facilitate the efficient installation of piping systems, leading to faster construction times.

5. Thermal Insulation GRP has excellent thermal insulating properties, making it suitable for applications where temperature regulation is critical. The material helps maintain the desired temperature of liquids transported through the pipes, making it ideal for systems dealing with sensitive materials.

Applications in Shipbuilding

GRP pipes and fittings are widely used across various applications in shipbuilding, including

grp pipes and fittings for ship building

- Ballast Systems GRP pipes are commonly utilized in ballast systems, which are essential for maintaining the stability of vessels. The lightweight nature of GRP contributes to the efficient operation of these systems, enhancing overall vessel performance.

- Cooling Water Systems The corrosion resistance of GRP makes it suitable for cooling water systems, where the pipes are often exposed to seawater. Utilizing GRP in these systems minimizes the risk of leaks and failures, ensuring optimal operation.

- Tank Construction GRP is often employed in the construction of storage tanks for various liquids on board, such as fuel, water, and waste. The material’s resistance to corrosion and chemical degradation ensures the safe storage of these critical substances.

- Deck Drainage Systems In shipbuilding, effective drainage is essential for maintaining safety and operability. GRP pipes are employed in deck drainage systems to efficiently channel water away from decks and prevent potential hazards.

Factors Driving Adoption

The growing awareness of environmental sustainability has significantly influenced the shift towards GRP materials in shipbuilding. With increasing regulations on emissions and waste management, shipbuilders are seeking materials that not only meet performance standards but also contribute to reducing the environmental impact of their operations. GRP aligns well with these goals and is being embraced as a greener alternative.

Moreover, advancements in manufacturing technologies have improved the quality and affordability of GRP products, making them more accessible to shipbuilders worldwide. As the maritime industry continues to evolve, the focus on innovative materials like GRP will play a crucial role in shaping the future of shipbuilding.

Conclusion

In conclusion, GRP pipes and fittings are becoming a preferred choice in shipbuilding due to their myriad benefits, including corrosion resistance, lightweight design, durability, and flexibility. As the industry strives for more sustainable practices and efficient designs, GRP materials will likely play an increasingly important role in the development of modern vessels, paving the way for a more advanced maritime future.