-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

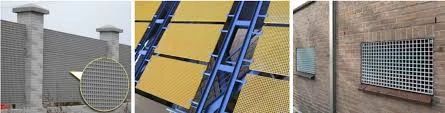

grp pipes and fittings for ship building

The Importance of GRP Pipes and Fittings in Shipbuilding

In the dynamic world of shipbuilding, materials play a critical role in determining the durability, efficiency, and safety of vessels. Among the leading materials making waves in this industry are Glass Reinforced Plastic (GRP) pipes and fittings. This composite material, known for its robust properties, offers a host of advantages, making it an ideal choice for various applications at sea.

Understanding GRP

Glass Reinforced Plastic (GRP) is a composite material made by combining glass fibers with polymer resin. The result is a lightweight yet incredibly strong material resistant to corrosion, chemicals, and extreme weather conditions. These properties make GRP particularly suitable for the demanding marine environment, where exposure to saltwater, humidity, and various substances is inevitable.

Advantages of GRP Pipes and Fittings

1. Corrosion Resistance One of the most significant advantages of GRP pipes is their resistance to corrosion. Unlike traditional materials such as steel, which can succumb to rust and degradation when exposed to seawater, GRP maintains its integrity over time. This property reduces maintenance costs and prolongs the lifespan of the piping systems on ships.

2. Lightweight GRP is significantly lighter than metal alternatives, which can lead to overall weight reduction in hull designs. This lightweight nature not only enhances fuel efficiency but also allows for greater cargo capacity without compromising stability.

3. Flexibility in Design GRP can be manufactured in a wide range of shapes and sizes, offering flexibility that traditional materials often cannot. This versatility allows shipbuilders to create custom-designed piping systems tailored to specific ship layouts and functions.

4. Thermal Insulation GRP exhibits excellent thermal insulation properties, making it an advantageous choice for systems requiring temperature regulation. This feature is particularly useful in preventing condensation, which can lead to mold and other issues in enclosed spaces.

grp pipes and fittings for ship building

5. Reduced Noise Levels The composition of GRP helps in dampening noise, contributing to a quieter environment on board. This is especially important in passenger vessels and luxury yachts, where comfort and tranquility are paramount.

Applications in Shipbuilding

GRP pipes and fittings are utilized in various applications within the shipbuilding industry

- Piping Systems From freshwater and wastewater systems to ballast and fuel piping, GRP pipes are increasingly being employed due to their reliability and performance. - Ventilation Systems Due to their lightweight nature and resistance to moisture, GRP is used in ventilation systems where corrosion resistance is crucial. - Fire Protection Systems GRP’s ability to withstand harsh conditions makes it suitable for ship fire protection systems. It can handle the high-pressure requirements without faltering.

- Cooling Systems The thermal insulation properties of GRP make it an excellent choice for cooling systems, where maintaining a specific temperature is essential for equipment efficiency.

Installation and Maintenance

While GRP pipes and fittings are easy to install, which can significantly reduce labor costs and time, proper installation practices must be followed to maximize their lifespan and efficacy. Maintenance is minimal compared to traditional piping systems, but regular checks for any signs of wear or damage can help ensure long-term performance.

Conclusion

In conclusion, the growing adoption of GRP pipes and fittings in the shipbuilding industry underscores a significant shift towards more innovative materials that enhance vessel performance and longevity. With their superior properties of corrosion resistance, lightweight, and flexibility, GRP components are setting new standards in maritime engineering. As the industry continues to evolve, the integration of GRP materials will likely become even more prevalent, leading to safer, more efficient, and environmentally friendly ships. The future of shipbuilding looks brighter with GRP at the helm, steering the industry towards new horizons of excellence.