-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 10, 2025 12:29

Back to list

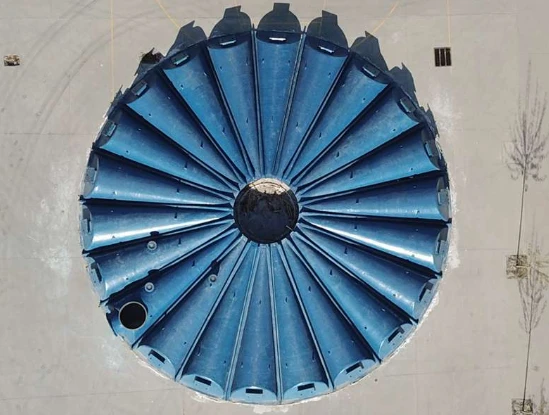

Clarifiers & Settlers

In industries where fluid transport is crucial, the GRP piping system has emerged as a leading choice. Known for both versatility and durability, GRP, or Glass Reinforced Plastic, offers unique advantages in various environments, surpassing traditional piping materials like metal and concrete. This article delves into the features and benefits of GRP piping systems, supported by authoritative expertise and real-world experiences.

Trust in GRP piping systems is fortified by rigorous testing and compliance with international standards. Manufacturers subject GRP pipes to ASTM, ISO, and EN specifications, guaranteeing performance and safety. These standards ensure that GRP pipes can handle temperature variations and physical stresses encountered in different installation scenarios, providing users with peace of mind regarding their operational reliability. Real-world case studies highlight the transformative impact of GRP piping systems. In regions with challenging geological conditions, such as earthquake-prone areas, GRP’s ability to withstand flexural stresses without cracking is invaluable. This resilience has been proven in installations in seismically active regions, where GRP pipes continue to perform flawlessly after events that compromise other materials. Environmental sustainability is yet another dimension where GRP scores highly. With increasing pressure on industries to reduce their carbon footprint, GRP stands out due to its lower environmental impact across its lifecycle. The production process of GRP emits less CO2 compared to metals, and it's also recyclable, aligning with global sustainability goals. As large corporations push for greener technologies, GRP provides an eco-friendly solution that does not sacrifice performance. Choosing a GRP piping system partners you with a reliable, expert-backed product that meets high-performance demands. Through decades of industry advancements, GRP has been tested and proven under stringent conditions, earning its reputation as a dependable choice in critical applications. By leveraging real-world experiences and authoritative insights, industries can trust GRP to deliver not just on expectations, but beyond them. In conclusion, GRP piping systems embody the pinnacle of modern engineering, effectively balancing functionality, durability, and sustainability. The integration of GRP in various sectors is set to grow as industries continue to prioritize efficiency and resilience. As such, the GRP piping system stands as a beacon of innovation, providing a trustworthy solution to some of the most demanding fluid transport challenges.

Trust in GRP piping systems is fortified by rigorous testing and compliance with international standards. Manufacturers subject GRP pipes to ASTM, ISO, and EN specifications, guaranteeing performance and safety. These standards ensure that GRP pipes can handle temperature variations and physical stresses encountered in different installation scenarios, providing users with peace of mind regarding their operational reliability. Real-world case studies highlight the transformative impact of GRP piping systems. In regions with challenging geological conditions, such as earthquake-prone areas, GRP’s ability to withstand flexural stresses without cracking is invaluable. This resilience has been proven in installations in seismically active regions, where GRP pipes continue to perform flawlessly after events that compromise other materials. Environmental sustainability is yet another dimension where GRP scores highly. With increasing pressure on industries to reduce their carbon footprint, GRP stands out due to its lower environmental impact across its lifecycle. The production process of GRP emits less CO2 compared to metals, and it's also recyclable, aligning with global sustainability goals. As large corporations push for greener technologies, GRP provides an eco-friendly solution that does not sacrifice performance. Choosing a GRP piping system partners you with a reliable, expert-backed product that meets high-performance demands. Through decades of industry advancements, GRP has been tested and proven under stringent conditions, earning its reputation as a dependable choice in critical applications. By leveraging real-world experiences and authoritative insights, industries can trust GRP to deliver not just on expectations, but beyond them. In conclusion, GRP piping systems embody the pinnacle of modern engineering, effectively balancing functionality, durability, and sustainability. The integration of GRP in various sectors is set to grow as industries continue to prioritize efficiency and resilience. As such, the GRP piping system stands as a beacon of innovation, providing a trustworthy solution to some of the most demanding fluid transport challenges.

Next:

Related Products