-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

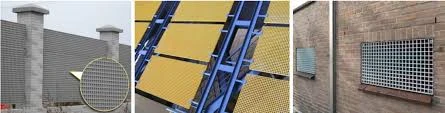

grp products for steel smelting plant

GRP Products for Steel Smelting Plants Enhancing Efficiency and Sustainability

In the realm of industrial operations, steel smelting plants are crucial players in the global economy, serving as the backbone for numerous industries, including construction, automotive, and manufacturing. As these facilities advance, innovation in materials and technologies becomes paramount, particularly in the quest for enhanced efficiency and sustainability. One notable advancement in this sector is the adoption of Glass Reinforced Plastic (GRP) products.

GRP, also known as fiberglass, is a composite material made of a polymer matrix reinforced with glass fibers. This combination endows GRP with exceptional properties, such as high strength-to-weight ratio, corrosion resistance, and durability. In steel smelting plants, these characteristics are invaluable, as they mitigate the effects of the harsh operating environments that typically involve extreme temperatures, chemical exposure, and mechanical stress.

One of the primary applications of GRP in steel smelting plants is in the construction of storage tanks and piping systems. Traditional materials, such as steel and concrete, can succumb to rust and corrosion, requiring frequent maintenance and replacement. In contrast, GRP tanks and pipes can withstand the aggressive chemical environments encountered in smelting processes, significantly reducing maintenance costs and downtime. Moreover, their lightweight nature simplifies installation and allows for more flexible design options, optimizing the layout of plant infrastructures.

grp products for steel smelting plant

Another key advantage of GRP products is their insulation properties. Insulating materials are crucial in steel smelting, as they help in maintaining the necessary temperatures during the smelting process while enhancing energy efficiency. GRP’s excellent thermal insulation capabilities contribute to reduced energy consumption, aligning with the global push for sustainable industrial practices.

Additionally, GRP products can facilitate improved safety in steel smelting plants. Their non-conductivity and resistance to heat make them an ideal choice for electrical enclosures and protective barriers, ensuring the safety of personnel and equipment alike. By reducing the risk of accidents and enhancing working conditions, GRP plays a vital role in fostering a culture of safety within the industry.

As the steel industry continues to grapple with environmental challenges, the need for sustainable solutions has never been more critical. GRP products contribute to this goal by enabling the implementation of efficient processes that minimize waste and reduce the carbon footprint of steel production.

In conclusion, the integration of GRP products in steel smelting plants represents a significant step towards modernizing the industry. With their superior properties, these materials enhance operational efficiency, promote safety, and contribute to sustainability efforts. As steel production evolves, the adoption of innovative materials like GRP will undoubtedly play a crucial role in shaping the future of steel manufacturing.