-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

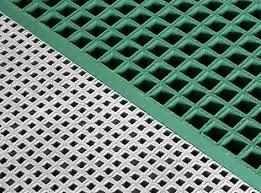

GRP Solutions for Steel Manufacturing Facilities and Smelting Operations

Innovations in GRP Products for Steel Smelting Plants

Steel smelting is a critical process in manufacturing high-quality steel, which serves as a foundation for countless industries ranging from construction and automotive to aerospace. As the demand for steel continues to rise globally, the need for effective and sustainable methods in steel production becomes increasingly important. One significant technological advancement to emerge in recent years is the use of Glass Reinforced Plastic (GRP) products in steel smelting plants. This article delves into the benefits and applications of GRP products, highlighting their role in enhancing efficiency and sustainability in the steel production process.

Understanding GRP Technology

Glass Reinforced Plastic, or GRP, is a composite material made from a polymer matrix reinforced with glass fibers. This combination results in a lightweight, durable, and corrosion-resistant material that is ideal for a variety of industrial applications. GRP products are utilized in numerous sectors, including construction, maritime, and chemical processing, due to their excellent mechanical properties and resistance to harsh environmental conditions.

In the context of steel smelting plants, GRP technology is revolutionizing equipment and facility design. The inherent characteristics of GRP make it a suitable material for components that can withstand the extreme conditions present in smelting operations.

Applications of GRP in Steel Smelting

1. Corrosion Resistance Steel smelting involves exposure to high temperatures and aggressive chemical environments. Traditional materials like steel and iron are subject to corrosion over time, leading to maintenance challenges and elevated operational costs. GRP's exceptional corrosion resistance significantly enhances equipment lifespan and reduces the need for frequent replacements or repairs.

2. Structural Components GRP can be used to fabricate structural components such as support beams, tanks, and piping systems. The lightweight nature of GRP allows for easier handling and installation, reducing labor costs and improving safety during construction and maintenance activities.

3. Fume Extraction Systems The smelting process generates various hazardous fumes and gases, which must be effectively managed to ensure worker safety and environmental compliance. GRP ducting systems are increasingly being used in fume extraction applications due to their resistance to corrosion and high temperatures. These systems maintain structural integrity even in the presence of caustic substances.

4. Insulation and Refractory Linings GRP materials can be utilized as insulation materials for furnaces and kilns, enhancing thermal efficiency within the smelting process. Additionally, GRP can be integrated into refractory linings, providing an excellent thermal barrier while withstanding the extreme conditions prevalent in steel production environments.

grp products for steel smelting plant

5. Waste Management Solutions Steel smelting generates a significant amount of waste, including slag, dust, and other by-products. GRP products are being used in waste management systems designed to contain and process these residues efficiently. Their durability and resistance to chemical attacks make GRP an ideal choice for waste containment solutions.

Benefits of GRP Products

Adopting GRP products in steel smelting plants offers several substantial benefits

- Cost-Efficiency While the initial investment in GRP products may be higher than conventional materials, the long-term savings associated with reduced maintenance, lower energy consumption, and extended lifespan make GRP a cost-effective choice.

- Environmental Sustainability As industries worldwide strive to minimize their ecological footprint, GRP products contribute to sustainability goals by reducing resource consumption and enhancing energy efficiency in smelting operations.

- Safety Improvements The use of GRP in high-risk environments can contribute to safer working conditions. Its lightweight properties reduce manual handling injury risks, while its non-conductive nature enhances electrical safety.

- Performance Consistency GRP products maintain their properties over time, ensuring consistent performance in demanding environments. This reliability is crucial in maintaining the productivity and output quality of steel smelting operations.

Conclusion

The integration of GRP products in steel smelting plants marks a significant evolution in technology aimed at improving efficiency, safety, and sustainability in steel production. As the industry continues to expand and face new challenges, innovative solutions like GRP will play an increasingly vital role in shape the future of steel manufacturing. By investing in advanced materials such as GRP, steel smelting plants can enhance operational resilience, reduce costs, and contribute to a more sustainable industrial landscape.