-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 21:55

Back to list

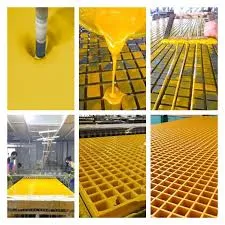

Winding Machines for Pipes & Tanks

When navigating the complexities of industrial emissions and pollution control, one product stands out the GRP scrubber. Esteemed across various industries, the GRP (Glass Reinforced Plastic) scrubber is renowned for its exceptional durability and efficiency in handling hazardous waste gases. This cutting-edge technology pairs the lightweight yet robust properties of GRP material with advanced scrubbing capabilities, setting a new standard in air pollution control.

In terms of authoritativeness, GRP scrubbers are engineered to comply with international standards such as ISO 14001 for environmental management systems. This adherence not only certifies their quality but also assures users of their reliability and effectiveness in real-world applications. Trustworthiness is further enhanced through rigorous testing and quality control processes certified by internationally recognized bodies. Regular inspections and performance evaluations ensure that each GRP scrubber functions at peak capacity, fostering the confidence of businesses that invest in this technology. By investing in GRP scrubbers, industries are better positioned to address environmental concerns while optimizing their processes. With a proven track record of performance, low maintenance requirements, and compliance with global environmental regulations, GRP scrubbers offer a sustainable solution for the future. In conclusion, the GRP scrubber epitomizes modern, efficient, and responsible industrial practices. This product's innovative use of material and design serves as a benchmark for sustainability and environmental consciousness. Given the increasing global focus on reducing industrial emissions, the GRP scrubber will continue to be instrumental in helping industries achieve their sustainability goals. As businesses worldwide strive to enhance their environmental footprint, investing in GRP scrubbers is an expert-backed, authoritative move supported by a history of trust and successful application.

In terms of authoritativeness, GRP scrubbers are engineered to comply with international standards such as ISO 14001 for environmental management systems. This adherence not only certifies their quality but also assures users of their reliability and effectiveness in real-world applications. Trustworthiness is further enhanced through rigorous testing and quality control processes certified by internationally recognized bodies. Regular inspections and performance evaluations ensure that each GRP scrubber functions at peak capacity, fostering the confidence of businesses that invest in this technology. By investing in GRP scrubbers, industries are better positioned to address environmental concerns while optimizing their processes. With a proven track record of performance, low maintenance requirements, and compliance with global environmental regulations, GRP scrubbers offer a sustainable solution for the future. In conclusion, the GRP scrubber epitomizes modern, efficient, and responsible industrial practices. This product's innovative use of material and design serves as a benchmark for sustainability and environmental consciousness. Given the increasing global focus on reducing industrial emissions, the GRP scrubber will continue to be instrumental in helping industries achieve their sustainability goals. As businesses worldwide strive to enhance their environmental footprint, investing in GRP scrubbers is an expert-backed, authoritative move supported by a history of trust and successful application.

Next:

Related Products