-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 15, 2025 01:26

Back to list

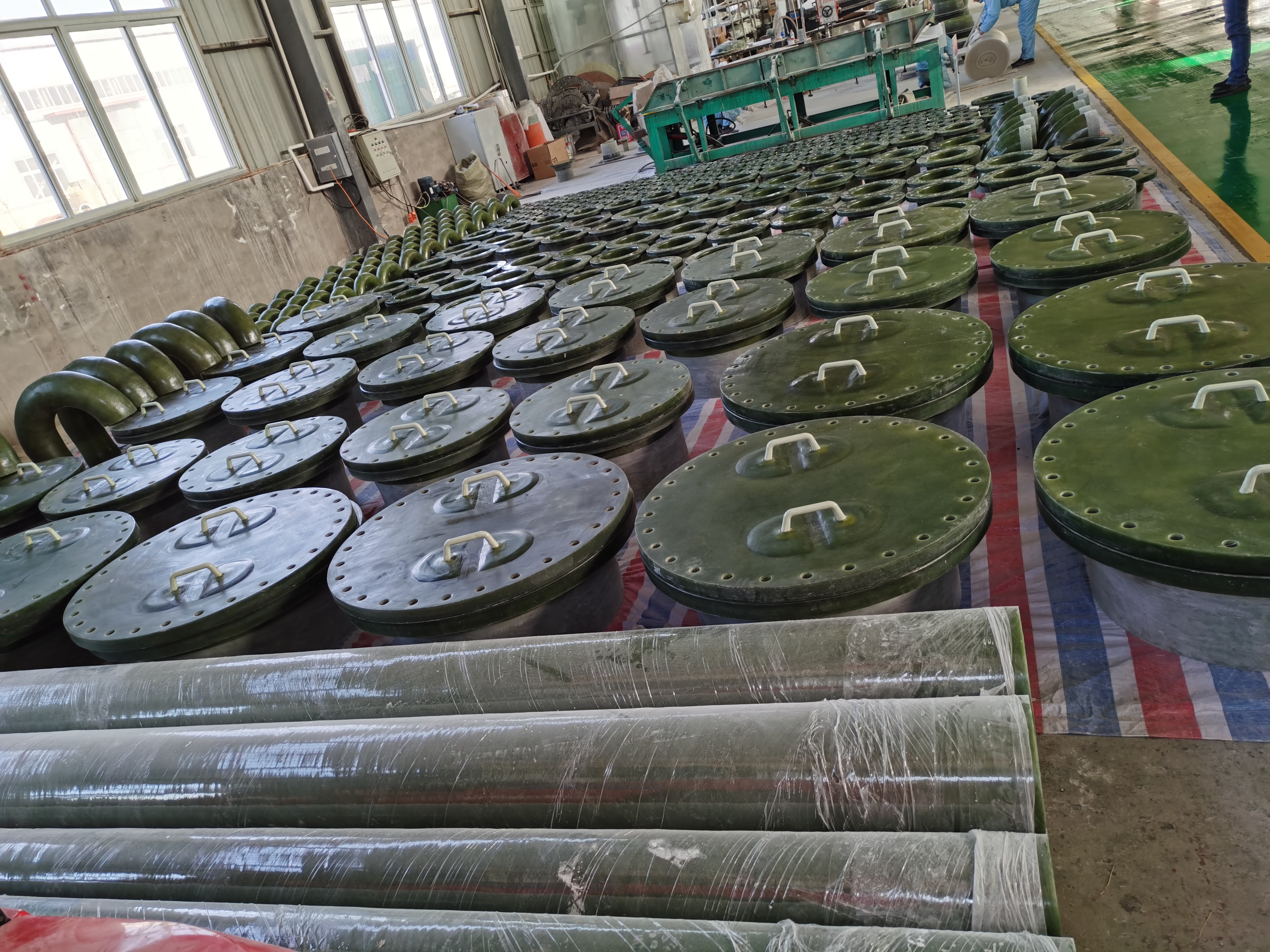

grp vessel

The term GRP vessel refers to a Glass Reinforced Plastic (GRP) structure widely used in various industries, including marine, chemical processing, wastewater management, and more. These vessels are lauded for their durability, corrosion resistance, and lightweight properties, making them a preferred choice for storage and processing applications.

The expertise of manufacturers is a crucial component when selecting GRP vessels. Leading manufacturers employ advanced fabrication techniques to enhance the structural integrity and aesthetic appeal of each vessel. Their commitment to quality is reflected in rigorous testing standards that ensure each vessel can withstand the mechanical stresses and environmental factors pertinent to its intended use. Consultation with these experts ensures that businesses select the right type of GRP vessel tailored to their operational needs. Authoritativeness in the market is demonstrated by manufacturers who consistently innovate based on customer feedback and technological advancements. Pioneers in the field continuously collaborate with research institutions to develop GRP vessels that not only meet but exceed industry standards. Partnerships with recognized certification bodies further consolidate their position as authoritative figures in the market, guaranteeing that end-users receive products certified for safety, quality, and performance. Trustworthiness is cemented through comprehensive post-sale support provided by reputable manufacturers. This includes maintenance services, warranty options, and technical support to address any operational concerns. Customers report high satisfaction levels due to the reliability and promptness of these services, which are critical in industries where downtime can lead to significant financial implications. In conclusion, GRP vessels represent a pivotal advancement across multiple sectors, offering a sustainable, durable, and cost-effective solution for various applications. Their unique properties provide an edge over traditional materials, making them indispensable in modern industrial practices. Trust in GRP vessels is not only built on technical specifications but also on the reputation and support of those who manufacture and endorse them. By choosing GRP vessels, industries invest in a future-proof solution that aligns with evolving environmental and economic demands.

The expertise of manufacturers is a crucial component when selecting GRP vessels. Leading manufacturers employ advanced fabrication techniques to enhance the structural integrity and aesthetic appeal of each vessel. Their commitment to quality is reflected in rigorous testing standards that ensure each vessel can withstand the mechanical stresses and environmental factors pertinent to its intended use. Consultation with these experts ensures that businesses select the right type of GRP vessel tailored to their operational needs. Authoritativeness in the market is demonstrated by manufacturers who consistently innovate based on customer feedback and technological advancements. Pioneers in the field continuously collaborate with research institutions to develop GRP vessels that not only meet but exceed industry standards. Partnerships with recognized certification bodies further consolidate their position as authoritative figures in the market, guaranteeing that end-users receive products certified for safety, quality, and performance. Trustworthiness is cemented through comprehensive post-sale support provided by reputable manufacturers. This includes maintenance services, warranty options, and technical support to address any operational concerns. Customers report high satisfaction levels due to the reliability and promptness of these services, which are critical in industries where downtime can lead to significant financial implications. In conclusion, GRP vessels represent a pivotal advancement across multiple sectors, offering a sustainable, durable, and cost-effective solution for various applications. Their unique properties provide an edge over traditional materials, making them indispensable in modern industrial practices. Trust in GRP vessels is not only built on technical specifications but also on the reputation and support of those who manufacture and endorse them. By choosing GRP vessels, industries invest in a future-proof solution that aligns with evolving environmental and economic demands.

Next:

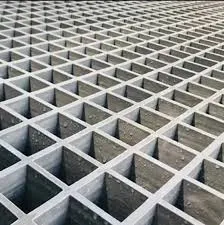

Related Products