-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Design Concepts for GRP Winding Machines in Modern Manufacturing Processes

Understanding Group Winding Machines A Comprehensive Overview

Group winding machines constitute a pivotal aspect of modern electrical engineering and manufacturing, particularly in the production of electric motors and generators. These machines are designed to optimize the winding processes while ensuring high efficiency and precision, which are essential for the performance of electric devices.

At the core of group winding machines is the technique known as ‘group winding’ where multiple coils are wound onto a core simultaneously. This innovative method reduces production time significantly compared to traditional winding processes. By enabling the winding of several wires at once, group winding machines improve productivity and consistency in manufacturing.

Understanding Group Winding Machines A Comprehensive Overview

One of the significant advantages of using group winding machines is the reduced labor costs associated with manual winding operations. Automation allows manufacturers to allocate human resources to other essential areas of production, leading to overall cost efficiency. Furthermore, the consistency achieved through automated winding can significantly reduce the risk of human error, ensuring that every coil is wound to the required specifications.

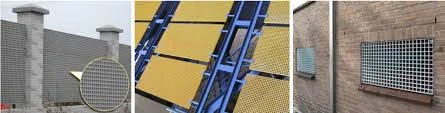

grp winding machine

Another key benefit of group winding machines is their scalability. They can be tailored to meet the specific production needs of various industries, ranging from small-scale manufacturing to large industrial operations. Manufacturers can adjust the number of coils being wound simultaneously to accommodate different product designs, making group winding machines versatile equipment in the production line.

Moreover, group winding technology has evolved to incorporate features that enhance energy efficiency. Many modern machines are designed to minimize energy consumption during the winding process, contributing to sustainable manufacturing practices. By utilizing energy-efficient motors and systems, manufacturers not only save costs but also reduce their environmental footprint.

The application of group winding machines extends beyond electric motors and generators. They are also utilized in the production of transformers, inductors, and even in the winding of certain types of cable. As technology progresses, group winding machines continue to adapt, incorporating advanced materials and construction techniques that enhance their operational capabilities.

In conclusion, group winding machines play a crucial role in the manufacturing processes of electrical components. Their ability to enhance productivity, reduce labor costs, ensure consistency, and provide energy efficiency makes them an invaluable asset in modern production lines. As industries evolve and demand for electric devices continues to rise, the importance of these machines will only increase. Manufacturers looking to improve their operational efficiency and product quality would do well to consider integrating group winding machines into their production processes. This technology not only represents a significant investment in modern manufacturing techniques but also embodies the future of electrical engineering.