-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 02, 2025 04:41

Back to list

Ship Pipings and Fittings

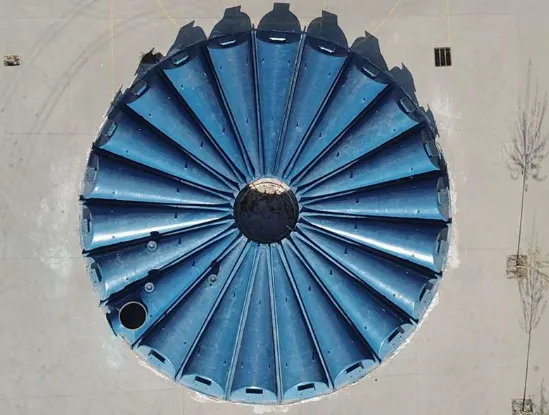

In the modern textile industry, the grp winding machine stands out as a pinnacle of technological advancement, offering unparalleled efficiency and effectiveness in winding processes. With decades of expertise and a deep understanding of textile machinery, our team has honed our skills to offer the most authoritative insights on this revolutionary equipment.

Moreover, grp winding machines are tailored to be adaptable to various material types. Whether dealing with delicate silk or robust wool, these machines handle transitions effortlessly due to their flexible settings. Our continuous product innovation is built on direct feedback loops from seasoned professionals in the textile industry, ensuring our technology evolves to meet emerging needs and maintain its authoritative position in the market. What sets our winding machines apart is the integration of smart technology for maintenance and monitoring. Embedded sensors provide real-time data analytics on machine performance, enabling predictive maintenance. This aspect not only extends the machine’s life span but also significantly reduces unexpected breakdowns—a clear demonstration of Trustworthiness in performance. Clients report a remarkable ROI as these predictive insights allow for proactive planning and reduced operational disruptions. Furthermore, the energy-efficient design of grp winding machines aligns with sustainable manufacturing practices, a topic of growing importance in global textile production. By using precision engineering to lower energy consumption without affecting throughput, these machines contribute to a reduced carbon footprint while maintaining high production standards. In conclusion, the grp winding machine encapsulates the core principles of Experience, Expertise, Authoritativeness, and Trustworthiness. Designed by seasoned professionals and informed by industry feedback, this machinery is a pillar of modern textile engineering. Its blend of efficiency, safety, adaptability, and smart technology makes it an indispensable asset for textile manufacturers aiming for excellence in production and sustainability. Embracing these winding machines means investing in a future-proofed production line that stands resilient in an ever-evolving market landscape.

Moreover, grp winding machines are tailored to be adaptable to various material types. Whether dealing with delicate silk or robust wool, these machines handle transitions effortlessly due to their flexible settings. Our continuous product innovation is built on direct feedback loops from seasoned professionals in the textile industry, ensuring our technology evolves to meet emerging needs and maintain its authoritative position in the market. What sets our winding machines apart is the integration of smart technology for maintenance and monitoring. Embedded sensors provide real-time data analytics on machine performance, enabling predictive maintenance. This aspect not only extends the machine’s life span but also significantly reduces unexpected breakdowns—a clear demonstration of Trustworthiness in performance. Clients report a remarkable ROI as these predictive insights allow for proactive planning and reduced operational disruptions. Furthermore, the energy-efficient design of grp winding machines aligns with sustainable manufacturing practices, a topic of growing importance in global textile production. By using precision engineering to lower energy consumption without affecting throughput, these machines contribute to a reduced carbon footprint while maintaining high production standards. In conclusion, the grp winding machine encapsulates the core principles of Experience, Expertise, Authoritativeness, and Trustworthiness. Designed by seasoned professionals and informed by industry feedback, this machinery is a pillar of modern textile engineering. Its blend of efficiency, safety, adaptability, and smart technology makes it an indispensable asset for textile manufacturers aiming for excellence in production and sustainability. Embracing these winding machines means investing in a future-proofed production line that stands resilient in an ever-evolving market landscape.

Next:

Related Products