-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 15, 2025 00:46

Back to list

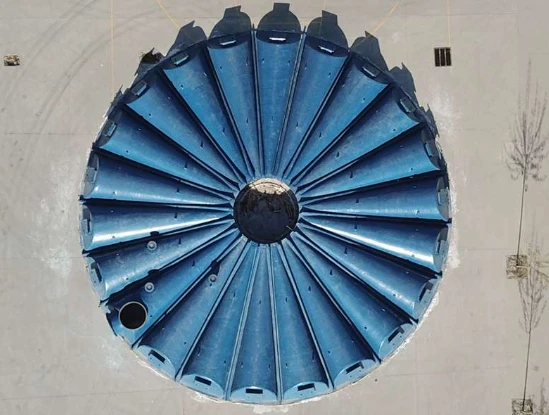

grp winding machine

Understanding the intricacies of a GRP winding machine requires not only an awareness of the machine's technical specifications but also a grasp of its practical applications in various industries. Glass Reinforced Plastic (GRP) winding machines have transformed the landscape of composite manufacturing, offering unparalleled precision and efficiency. But what sets a superior GRP winding machine apart, and how can it elevate manufacturing processes?

Moreover, user testimonials and case studies serve as valuable insights into the trustworthiness of a GRP winding machine. Real-world experiences shared by stakeholders reveal the machine's performance under different operational conditions. An example would be a leading aerospace component manufacturer crediting their GRP winding machine for improving production timelines while maintaining rigorous safety standards – a testament to both the machine's reliability and the manufacturer's expertise. Economic considerations also play a crucial role in machine selection. GRP winding machines represent a significant investment; hence, a cost-benefit analysis is imperative. Evaluating the machine in terms of speed, precision, and long-term operational costs against manual methods can offer clarity to decision-makers. The potential for decreased labor costs, accelerated production rates, and reduced material waste highlights the financial prudence of such an investment. Expertise in the operation and maintenance of GRP winding machines can significantly enhance their performance. A thorough understanding of software controls and maintenance routines ensures minimal downtimes and prolongs the machine's operational life. Regular updates and calibration checks, guided by an expert team, help maintain the machine's efficiency, thereby ensuring its output remains consistent and within defined quality metrics. In conclusion, a GRP winding machine stands as a cornerstone of modern composite manufacturing, offering unparalleled benefits in precision, adaptability, and sustainability. When augmented by expert knowledge, reliable service support, and real-world endorsements, it becomes a powerful tool essential for industries dedicated to innovation and excellence. The trustworthiness of a GRP winding machine is not only defined by its technical prowess but also by the holistic support ecosystem around it, reinforcing its status as a pivotal asset in manufacturing technology.

Moreover, user testimonials and case studies serve as valuable insights into the trustworthiness of a GRP winding machine. Real-world experiences shared by stakeholders reveal the machine's performance under different operational conditions. An example would be a leading aerospace component manufacturer crediting their GRP winding machine for improving production timelines while maintaining rigorous safety standards – a testament to both the machine's reliability and the manufacturer's expertise. Economic considerations also play a crucial role in machine selection. GRP winding machines represent a significant investment; hence, a cost-benefit analysis is imperative. Evaluating the machine in terms of speed, precision, and long-term operational costs against manual methods can offer clarity to decision-makers. The potential for decreased labor costs, accelerated production rates, and reduced material waste highlights the financial prudence of such an investment. Expertise in the operation and maintenance of GRP winding machines can significantly enhance their performance. A thorough understanding of software controls and maintenance routines ensures minimal downtimes and prolongs the machine's operational life. Regular updates and calibration checks, guided by an expert team, help maintain the machine's efficiency, thereby ensuring its output remains consistent and within defined quality metrics. In conclusion, a GRP winding machine stands as a cornerstone of modern composite manufacturing, offering unparalleled benefits in precision, adaptability, and sustainability. When augmented by expert knowledge, reliable service support, and real-world endorsements, it becomes a powerful tool essential for industries dedicated to innovation and excellence. The trustworthiness of a GRP winding machine is not only defined by its technical prowess but also by the holistic support ecosystem around it, reinforcing its status as a pivotal asset in manufacturing technology.

Related Products