-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Pressure Fiberglass Piping Solutions for Industrial Applications and Water Management Systems

High-Pressure Fiberglass Piping Systems A Comprehensive Overview

In various industrial applications, the need for robust and reliable piping systems is vital, particularly in environments requiring the transfer of corrosive substances under high pressure. High-pressure fiberglass piping systems have emerged as a preferred choice for many industries, thanks to their unique combination of strength, durability, and resistance to harsh chemicals. This article explores the advantages, applications, and considerations associated with high-pressure fiberglass piping systems.

Advantages of High-Pressure Fiberglass Piping Systems

1. Corrosion Resistance One of the most significant benefits of fiberglass piping is its resistance to corrosion. Unlike traditional metal pipes that can rust or degrade when exposed to aggressive chemicals, fiberglass pipes maintain their integrity over time, even in corrosive environments. This quality is particularly crucial in industries like chemical processing, wastewater treatment, and oil and gas.

2. Lightweight High-pressure fiberglass pipes are significantly lighter than metal pipes. This characteristic makes them easier to handle during installation and maintenance, reducing labor costs and improving safety. The lightweight nature of fiberglass also allows for more straightforward logistics and transportation, facilitating installation in remote or challenging locations.

3. Strength and Durability While fiberglass is lightweight, it does not compromise on strength. High-pressure fiberglass piping systems are designed to withstand significant pressure levels, making them suitable for applications that require the transportation of fluids under intense conditions. Additionally, fiberglass pipes exhibit exceptional impact resistance, which is crucial in environments prone to physical wear and tear.

4. Thermal Insulation Fiberglass piping systems also provide excellent thermal insulation properties. This feature is particularly beneficial in applications dealing with temperature-sensitive fluids, as it helps maintain the desired temperature without excessive energy loss. This can lead to increased energy efficiency and reduced operating costs.

5. Cost-Effectiveness Although the initial investment in fiberglass piping systems may be higher than traditional materials, the long-term savings in maintenance, repair, and replacement costs can be substantial. The durability and longevity of fiberglass piping can lead to lower lifecycle costs when compared to metal alternatives.

Applications of High-Pressure Fiberglass Piping Systems

High-pressure fiberglass piping systems are utilized across various industries, including

- Chemical Processing The ability of fiberglass to withstand corrosive chemicals makes it ideal for transporting acids, bases, and other reactive substances

.high-pressure fiberglass piping system

- Oil and Gas In oil and gas operations, fiberglass piping is often used for transporting fluids and natural gas at high pressures, benefiting from its strength and resistance to harsh environments.

- Water Treatment Fiberglass pipes are widely used in wastewater treatment and potable water systems due to their corrosion resistance and longevity.

- Power Generation The energy sector uses fiberglass piping for transporting steam and water, where high pressure is a common requirement.

Considerations for High-Pressure Fiberglass Piping Systems

While high-pressure fiberglass piping systems offer numerous advantages, several factors should be considered during selection and installation

1. Temperature Limits It is essential to understand the temperature limitations of fiberglass materials, as excessive heat can affect their integrity.

2. Installation Expertise Proper installation is crucial to ensure optimal performance and longevity. It is vital to engage experienced professionals who understand the specific requirements of fiberglass piping systems.

3. Compatibility with Fluids While fiberglass is resistant to many chemicals, it is essential to evaluate the compatibility of the piping material with the specific fluids being transported.

4. Regulatory Compliance Ensure that the selected fiberglass piping systems meet industry standards and regulations for safety and performance.

Conclusion

High-pressure fiberglass piping systems represent a versatile and reliable solution for modern industrial applications. Their unique properties, including corrosion resistance, lightweight design, and durability, make them an excellent choice for various sectors. By understanding the advantages and considerations associated with these systems, businesses can make informed decisions that enhance operational efficiency, safety, and cost-effectiveness in their piping solutions. As industries continue to evolve, high-pressure fiberglass piping will undoubtedly play a crucial role in meeting the challenges of transporting fluids in demanding environments.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

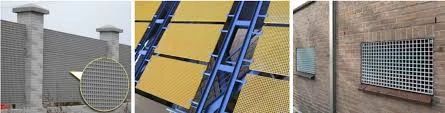

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025