-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Quality Fiberglass 90 Degree Elbow for Durable Plumbing and Industrial Applications

Understanding Fiberglass 90 Degree Elbows Applications and Benefits

Fiberglass has become an essential material in several industries due to its unique properties, combining strength, durability, and lightweight characteristics. One of the most common applications of fiberglass is in the manufacturing of piping systems, particularly the fiberglass 90 degree elbow. This article delves into the characteristics, applications, and benefits of fiberglass 90 degree elbows, highlighting their significance in modern engineering and manufacturing.

A fiberglass 90 degree elbow is a type of fitting used in piping systems to change the direction of flow. As the name suggests, it facilitates a 90-degree turn in the pipework, allowing for flexible layouts and efficient design in various applications. This component is critical in ensuring smooth transitions within plumbing, chemical processing, and HVAC systems. The non-corrosive nature of fiberglass makes these elbows particularly beneficial in environments where traditional metal fittings might degrade over time due to exposure to harsh chemicals or moisture.

One of the standout features of fiberglass is its strength-to-weight ratio. Fiberglass pipes and fittings, including 90 degree elbows, are significantly lighter than their metal counterparts, which eases installation and transport. The reduced weight also translates to lower structural loads, making it easier to design and engineer support systems for the entire piping network. Furthermore, since fiberglass does not corrode, it can withstand extreme environments while offering longevity and reduced maintenance costs.

fiberglass 90 degree elbow

In chemical processing, the use of fiberglass 90 degree elbows is especially prevalent due to their resistance to a wide range of chemicals. Industries utilizing acids, alkalis, and other reactive substances rely on fiberglass to maintain the integrity of their piping systems. This durability significantly reduces the risk of leaks and failures, which could lead to costly downtime and environmental hazards. The ability to customize fiberglass fittings to specific dimensions and designs further enhances their versatility, making them ideal for a wide range of applications.

Another area where fiberglass 90 degree elbows shine is in water and wastewater management. The smooth interior surfaces of fiberglass pipes reduce friction loss, leading to more efficient fluid flow. This property is crucial when designing systems for potable water distribution or effluent handling. Additionally, the resistance of fiberglass to biological growth ensures that systems remain clean and operational over extended periods.

The installation of fiberglass 90 degree elbows is also a streamlined process. While traditional metal fittings may require welding or complicated joining methods, fiberglass components can often be installed using adhesive or mechanical fittings, reducing labor costs and installation time. This ease of use is further supported by the lightweight nature of fiberglass, allowing for quick adjustments and modifications on site.

In summary, fiberglass 90 degree elbows represent a significant advancement in piping technology, combining their lightweight design with exceptional strength and chemical resistance. As industries continue to seek sustainable and cost-effective solutions, fiberglass products remain an attractive option. Their applications span various sectors, including construction, chemical processing, and water management, making them indispensable in modern infrastructure. In a world that prioritizes efficiency and durability, fiberglass 90 degree elbows offer a reliable solution for directing flow and maintaining system integrity, ensuring they will remain a crucial component in piping systems for years to come.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

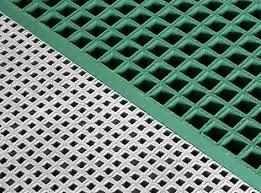

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025