-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

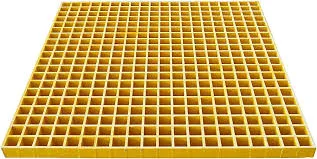

High-Quality Food Grade Equipment for Enhanced Safety and Efficiency in Food Processing Industries

Understanding FRP Food Grade Equipment An Overview

In the food industry, maintaining hygiene and safety standards is paramount. One of the key considerations in food processing and handling is the materials used in the equipment. Among the various materials available, Fiber Reinforced Plastics (FRP) have gained significant attention due to their advantageous properties. This article explores the significance of FRP food grade equipment, its benefits, and its applications in the food industry.

What is FRP?

Fiber Reinforced Plastics (FRP) are composite materials made from a polymer matrix reinforced with fibers. The most common fibers used are glass, carbon, and aramid. The combination of these materials results in a lightweight yet extremely strong product that can withstand various environmental conditions. The versatility of FRP allows it to be tailored for specific uses, including high-temperature resistance, chemical resistance, and structural integrity.

Benefits of FRP Food Grade Equipment

1. Hygienic Properties One of the primary advantages of FRP is its non-porous surface, which minimizes the risk of bacterial growth. This hygienic property makes FRP an ideal choice for food contact applications where sanitation is critical. Unlike metal or wood, which can harbor bacteria, FRP can be easily cleaned and sanitized, ensuring that food safety standards are consistently met.

2. Chemical Resistance The food processing industry often involves exposure to various chemicals, including cleaning agents, acids, and alkalis. FRP materials are resistant to many of these substances, preventing degradation and ensuring longevity. This chemical resistance extends the lifespan of equipment, reducing replacement costs and downtime.

3. Lightweight and Strong FRP is significantly lighter than metal, which adds to its ease of use and installation. Despite its light weight, FRP boasts impressive strength, making it suitable for equipment that requires durability and resilience under stress. This strength-to-weight ratio is particularly advantageous in food processing plants where equipment is frequently moved or adjusted.

4. Temperature Tolerance In food processing, temperature control is crucial. FRP can withstand a wide range of temperatures, making it suitable for various applications, including both freezing and heating processes. This versatility allows for its use in different stages of food preparation and preservation.

frp food grade equipment

5. Customization The manufacturing process of FRP allows for significant customization. Equipment can be designed in unique shapes or sizes to fit specific operational requirements. Moreover, it can be produced in various colors, facilitating organization in a bustling food processing environment.

Applications of FRP in the Food Industry

FRP food grade equipment finds its applications across various sectors of the food industry, including

- Storage Tanks and Containers FRP tanks are used for storing liquids and bulk materials, ensuring that the contents remain uncontaminated. Their lightweight nature facilitates easier transportation and handling.

- Conveyor Systems Many food processing plants rely on conveyor systems for efficiency. FRP components can withstand the rigors of continuous operation while maintaining hygiene.

- Processing Equipment From mixing tanks to slicers and dicing machines, FRP parts can be integrated into various food processing equipment, enhancing performance while adhering to food safety regulations.

- Curing Racks and Shelving FRP shelves and racks provide a safe, durable space for curing and organizing food products during processing.

Conclusion

The incorporation of FRP food grade equipment in the food industry represents a significant advancement in maintaining hygiene, safety, and efficiency in food handling and processing. With their myriad benefits, FRP materials are becoming a preferred choice for various applications, providing long-lasting solutions that meet the demanding needs of food production. Investing in FRP equipment not only ensures compliance with food safety standards but also enhances operational efficiency, ultimately leading to better quality products for consumers.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025