-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

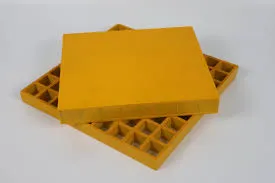

high pressure fiberglass pipe

High-pressure fiberglass pipes are increasingly becoming a popular choice in various industries due to their impressive strength, lightweight characteristics, and resistance to corrosion. These pipes, comprised primarily of glass fibers and resin, offer a viable alternative to traditional materials such as metal and plastic, especially in high-pressure applications.

One of the foremost advantages of fiberglass pipes is their ability to withstand high pressures while maintaining structural integrity. This makes them ideal for use in hydraulic systems, chemical processing plants, and oil and gas pipelines, where safety and reliability are paramount. The unique composition of fiberglass allows it to excel in demanding environments, effectively tackling pressures that would typically challenge metals, without the risk of rust or corrosion.

.

Corrosion resistance is another critical factor that elevates the appeal of high-pressure fiberglass pipes. In industries that handle aggressive chemicals and substances, the risk of material degradation poses serious operational threats. Fiberglass inherently resists chemical attack, which means these pipes maintain their performance over time, significantly reducing the need for frequent replacements and repairs. This longevity contributes to lower lifecycle costs and enhances overall system reliability.

high pressure fiberglass pipe

The adaptability of fiberglass pipes is another noteworthy feature. They can be manufactured in various diameters and thicknesses to meet specific project requirements. This customizability ensures that they suit a wide range of applications—from water transport systems to industrial wastewater management—accommodating the unique specifications of each case.

Furthermore, advancements in manufacturing techniques are continually improving the performance and versatility of fiberglass pipes. The introduction of advanced resin systems and enhanced fiber architectures has resulted in products that can handle even higher pressures and temperatures. As a result, these high-pressure fiberglass pipes are becoming more widely accepted in both new construction projects and renovation endeavors.

In summary, high-pressure fiberglass pipes stand out for their remarkable strength, lightweight properties, and resilience against corrosion. These features not only promote their use in a variety of high-pressure applications but also align with the growing demand for sustainable and cost-effective solutions in modern industrial processes. As industries evolve and push the boundaries of technology, high-pressure fiberglass pipes are well-positioned to play a critical role in the future of infrastructure development.