-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 10, 2025 09:30

Back to list

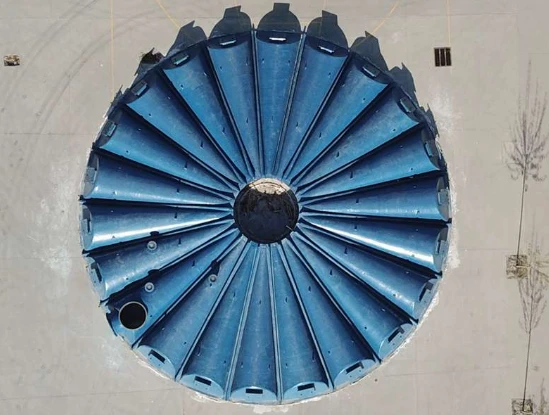

high pressure fiberglass pipe

The industrial landscape has witnessed a notable rise in the utilization of high-pressure fiberglass pipe, a technology that is revolutionizing piping systems across various sectors. These pipes, made from glass fibers embedded in a resin matrix, offer a unique blend of benefits that elevate their reliability and efficiency, making them an indispensable element in sophisticated operations requiring high-pressure transmission.

In terms of expertise, manufacturers of high-pressure fiberglass pipes employ cutting-edge technology and rigorous quality control processes to ensure unparalleled performance. These pipes are subjected to extensive testing, including hydrostatic testing and cyclic pressure testing, to validate their integrity and performance under extreme conditions. This level of scrutiny ensures that the pipes meet international standards, providing assurance of their quality and reliability to businesses that cannot afford compromise. Authoritativeness in the field of high-pressure fiberglass pipe technology is demonstrated through consistent innovation and adaptation. Pioneers in this industry continually strive to enhance the performance characteristics of these pipes by integrating advanced materials and manufacturing techniques. Research and development play a crucial role, with ongoing studies focused on improving the tensile strength and pressure ratings of these pipes, ensuring that they remain at the forefront of industry requirements. Trustworthiness is inherent in the reputation of companies producing high-pressure fiberglass pipes. With decades of experience and a proven track record, these manufacturers have become synonymous with quality and reliability. Certifications from recognized industry bodies further reinforce their credibility and commitment to excellence, ensuring that end-users receive products that meet or exceed their expectations. In conclusion, high-pressure fiberglass pipes are transforming the infrastructure landscape with their unmatched combination of durability, cost-efficiency, and performance. Their adoption across various sectors underscores their adaptability and reliability, positioning them as a preferred choice for modern piping solutions. As industries increasingly prioritize sustainability and efficiency, the role of high-pressure fiberglass pipes will continue to expand, reflecting their indispensability in contemporary engineering and construction projects.

In terms of expertise, manufacturers of high-pressure fiberglass pipes employ cutting-edge technology and rigorous quality control processes to ensure unparalleled performance. These pipes are subjected to extensive testing, including hydrostatic testing and cyclic pressure testing, to validate their integrity and performance under extreme conditions. This level of scrutiny ensures that the pipes meet international standards, providing assurance of their quality and reliability to businesses that cannot afford compromise. Authoritativeness in the field of high-pressure fiberglass pipe technology is demonstrated through consistent innovation and adaptation. Pioneers in this industry continually strive to enhance the performance characteristics of these pipes by integrating advanced materials and manufacturing techniques. Research and development play a crucial role, with ongoing studies focused on improving the tensile strength and pressure ratings of these pipes, ensuring that they remain at the forefront of industry requirements. Trustworthiness is inherent in the reputation of companies producing high-pressure fiberglass pipes. With decades of experience and a proven track record, these manufacturers have become synonymous with quality and reliability. Certifications from recognized industry bodies further reinforce their credibility and commitment to excellence, ensuring that end-users receive products that meet or exceed their expectations. In conclusion, high-pressure fiberglass pipes are transforming the infrastructure landscape with their unmatched combination of durability, cost-efficiency, and performance. Their adoption across various sectors underscores their adaptability and reliability, positioning them as a preferred choice for modern piping solutions. As industries increasingly prioritize sustainability and efficiency, the role of high-pressure fiberglass pipes will continue to expand, reflecting their indispensability in contemporary engineering and construction projects.

Related Products