-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 11, 2025 12:59

Back to list

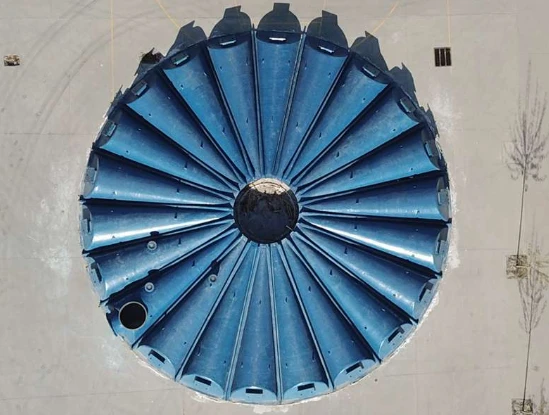

hollow drill rods for efficient drilling operations in the field

Hollow drill rods are revolutionizing the way industries approach drilling operations in the field. Offering unparalleled efficiency and reliability, these advanced tools have become indispensable in various sectors, including mining, construction, and geotechnical investigations. With the constant evolution of technology, it's crucial to delve into the Experience, Expertise, Authoritativeness, and Trustworthiness inherent in hollow drill rods and how they optimize drilling operations.

Trustworthiness in hollow drill rods emanates from the transparency of their manufacturing processes and the rigorous quality control measures in place. Reputable manufacturers provide detailed documentation about the composition, testing protocols, and performance metrics of their rods. This level of transparency instills confidence among buyers that they are investing in a proven and reliable product. Furthermore, many companies offer extensive warranties and customer support, ensuring that users have a direct line of assistance when needed. The establishment of service networks and maintenance facilities further consolidates this trust, offering users peace of mind knowing that technical support is readily available. In addition to these foundational pillars, hollow drill rods present several practical advantages that make them indispensable in the field. Their lightweight construction allows for easier handling and quicker assembly, which is particularly beneficial in remote or constrained drilling sites. This not only enhances overall productivity but also reduces operator fatigue, thereby promoting safety. The reduced material volume of hollow rods facilitates faster penetration into various substrates, be it rock, soil, or other geological formations. This efficiency is especially crucial in time-sensitive projects where delays can lead to significant cost overruns. Integrating hollow drill rods into existing drilling systems is straightforward, thanks to their compatibility with standard drilling rigs and accessories. This adaptability means that operators do not require specialized equipment or training to use these advanced rods effectively. Furthermore, their design often includes features that enable easy monitoring and data collection during drilling operations. For instance, sensors can be placed within the hollow section to measure parameters such as pressure, temperature, and flow rate. This data-driven approach provides invaluable insights that help in optimizing drilling strategies and decision-making. In summary, hollow drill rods embody the pinnacle of advanced drilling technologies, underpinned by robust Experience, Expertise, Authoritativeness, and Trustworthiness. Their development is rooted in years of industry knowledge, driven by expert engineering, validated by authoritative endorsements, and sustained by transparent and trustworthy manufacturing practices. As industries continue to prioritize efficiency and reliability, these innovative tools offer a solution that meets the demands of modern drilling operations. With their proven advantages and user-centric features, hollow drill rods are set to remain a cornerstone in achieving optimal drilling performance in diverse field conditions.

Trustworthiness in hollow drill rods emanates from the transparency of their manufacturing processes and the rigorous quality control measures in place. Reputable manufacturers provide detailed documentation about the composition, testing protocols, and performance metrics of their rods. This level of transparency instills confidence among buyers that they are investing in a proven and reliable product. Furthermore, many companies offer extensive warranties and customer support, ensuring that users have a direct line of assistance when needed. The establishment of service networks and maintenance facilities further consolidates this trust, offering users peace of mind knowing that technical support is readily available. In addition to these foundational pillars, hollow drill rods present several practical advantages that make them indispensable in the field. Their lightweight construction allows for easier handling and quicker assembly, which is particularly beneficial in remote or constrained drilling sites. This not only enhances overall productivity but also reduces operator fatigue, thereby promoting safety. The reduced material volume of hollow rods facilitates faster penetration into various substrates, be it rock, soil, or other geological formations. This efficiency is especially crucial in time-sensitive projects where delays can lead to significant cost overruns. Integrating hollow drill rods into existing drilling systems is straightforward, thanks to their compatibility with standard drilling rigs and accessories. This adaptability means that operators do not require specialized equipment or training to use these advanced rods effectively. Furthermore, their design often includes features that enable easy monitoring and data collection during drilling operations. For instance, sensors can be placed within the hollow section to measure parameters such as pressure, temperature, and flow rate. This data-driven approach provides invaluable insights that help in optimizing drilling strategies and decision-making. In summary, hollow drill rods embody the pinnacle of advanced drilling technologies, underpinned by robust Experience, Expertise, Authoritativeness, and Trustworthiness. Their development is rooted in years of industry knowledge, driven by expert engineering, validated by authoritative endorsements, and sustained by transparent and trustworthy manufacturing practices. As industries continue to prioritize efficiency and reliability, these innovative tools offer a solution that meets the demands of modern drilling operations. With their proven advantages and user-centric features, hollow drill rods are set to remain a cornerstone in achieving optimal drilling performance in diverse field conditions.

Related Products