-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

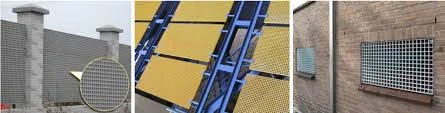

Innovative Solutions for Lightweight FRP Tanks and Their Applications in Various Industries

Understanding PP FRP Tanks A Comprehensive Overview

In recent years, the demand for high-performance, corrosion-resistant storage solutions has surged across various industries, including chemicals, water treatment, and food processing. One such innovation that has emerged in response to these needs is the PP FRP tank. Combining the benefits of polypropylene (PP) and fiber-reinforced plastic (FRP), these tanks offer an optimal solution for a wide range of applications.

What Are PP FRP Tanks?

PP FRP tanks are composite storage vessels made from a combination of polypropylene, a thermoplastic polymer known for its durability and resistance to corrosion, and fiber-reinforced plastic, a composite material that contains fiberglass or other fibers embedded in a resin. This combination of materials allows for tanks that are not only lightweight but also incredibly robust, able to withstand harsh environmental conditions.

Key Features and Benefits

1. Corrosion Resistance One of the foremost advantages of PP FRP tanks is their outstanding resistance to corrosive substances. Unlike traditional metal tanks, which can rust or degrade over time, PP FRP tanks retain their integrity even when exposed to aggressive chemicals and environmental factors, making them ideal for industries that handle hazardous materials.

2. Lightweight The composite nature of these tanks results in significantly reduced weight compared to traditional storage solutions. This feature simplifies the installation process and reduces transportation costs, making PP FRP tanks a more economical option over their lifespan.

3. Durability The reinforced structure of FRP provides excellent structural integrity, allowing these tanks to withstand impacts and stresses that would compromise the integrity of less resilient materials. This durability extends the operational life of the tank, further enhancing its cost-effectiveness.

pp frp tank

4. Versatility PP FRP tanks can be customized in terms of size and capacity to meet specific needs, ranging from small-scale applications to large industrial systems. This versatility is crucial in industries where space is a constraint or where specialized storage requirements exist.

5. Temperature Resistance These tanks can handle a wide range of temperatures, making them suitable for both heated and chilled applications. This feature is particularly beneficial in processes that involve thermal fluctuations, ensuring the safe storage of substances under varying conditions.

Applications of PP FRP Tanks

PP FRP tanks have found widespread usage across multiple sectors due to their numerous advantages. In the chemical industry, they are often used for the storage of corrosive liquids such as acids and alkalis. In water treatment facilities, they serve as storage solutions for both treated and untreated water, ensuring that systems remain efficient and compliant with safety regulations.

Additionally, the food processing industry utilizes PP FRP tanks for storing ingredients and products, as these tanks do not leach harmful substances, thereby protecting product integrity. Their adaptability also allows for use in agricultural settings, particularly for the storage of fertilizers and pesticides.

Conclusion

As industries continue to evolve and regulations on safety and environmental impact become stricter, the significance of durable and efficient storage solutions like PP FRP tanks will only increase. Their unique combination of lightweight characteristics, corrosion resistance, and customizability positions them as a preferred choice for a myriad of applications. Investing in PP FRP tanks not only ensures compliance with safety standards but also contributes to a more sustainable and efficient operational framework.